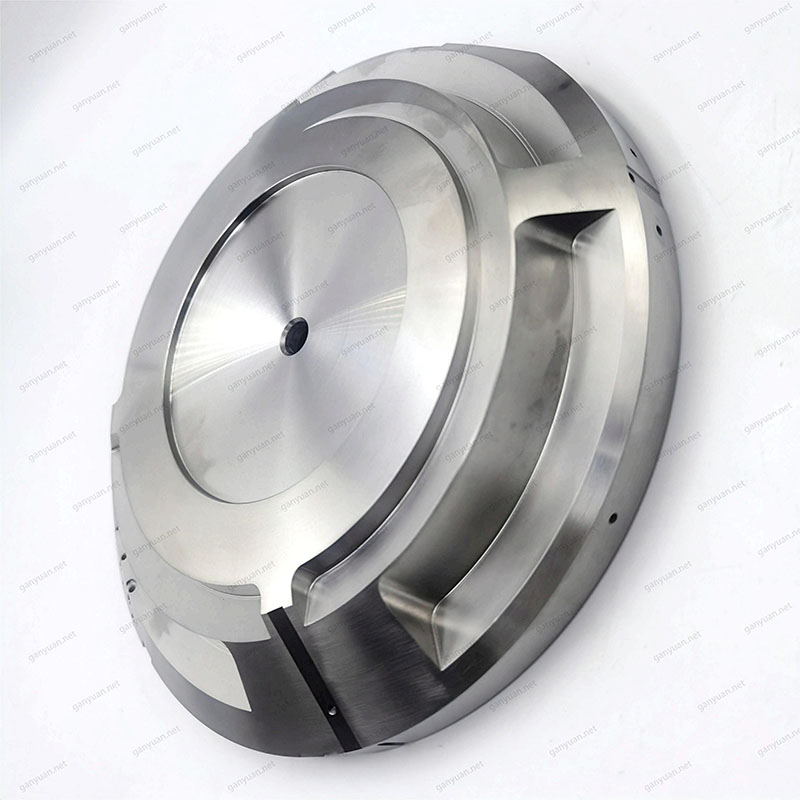

In the realm of industrial automation, where precision and reliability are non-negotiable, Stainless Steel Vibrating Discs emerge as the cornerstone of efficient material handling. Dongguan Ganyuan Hardware Technology Co., Ltd. combines decades of engineering expertise with a client-centric approach to deliver vibrating discs that not only meet but exceed the rigorous demands of modern manufacturing. Let’s explore how our stainless steel vibrating discs redefine precision in motion.

Product Description

| Production type |

Custom production and processing |

Material |

Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

| Processing methods |

CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting |

Processing Equipment |

CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting,Cnc Auto Part |

| Accuracy |

±0.02mm |

Whether proofing |

yes |

| Is it customized |

yes |

Proofing time |

7-15 days |

| OEM/ODM |

OEM ODM CNC machining service |

surface treatment |

Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin |

Dongguan, China |

Quotations |

FOB |

| Business Type: |

Manufacturer/Factory & Trading Company |

Main Products: |

CNC parts; Machining parts;PCB material wheels |

| Management System Certification: |

ISO 9001:2015 |

Average Lead Time: |

Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

Crafted from premium-grade stainless steel (304/316), our vibrating discs offer:

-

- Corrosion Resistance: Ideal for harsh environments, including humid workshops, chemical processing zones, or applications involving liquid contact (e.g., medical device assembly, food packaging).

- High Strength & Durability: Withstand continuous vibration, heavy loads, and high-frequency operation without compromising performance, ensuring a long service life even in high-stress industrial settings.

- Hygienic Design: Smooth surfaces and non-porous material make cleaning effortless, adhering to strict hygiene standards in industries like pharmaceuticals and food processing.

Our vibrating discs are more than just components—they’re precision-engineered systems:

Using advanced spiral tracks, grooves, and sorting mechanisms, our discs ensure consistent alignment of small parts (screws, connectors, bearings, etc.), reducing manual intervention and minimizing production errors.

- Frequency and amplitude controls allow seamless integration with diverse production lines, accommodating parts of varying sizes (from 0.5mm micro-components to 50mm industrial fasteners).

- Low-noise operation and stable vibration patterns enhance workplace safety and efficiency.

No two automation challenges are the same. Our team collaborates closely with you to design vibrating discs that fit your:

- Part Geometry: Complex shapes, delicate components, or irregularly sized parts? We engineer specialized tracks and sorting features.

- Production Speed: From low-volume prototyping to high-speed mass production, our discs scale with your throughput requirements.

- Environmental Conditions: Whether it’s extreme temperatures, corrosive atmospheres, or cleanroom environments, we tailor materials and finishes to suit.

Our Stainless Steel Vibrating Discs excel in diverse sectors:

- Electronics: Feeding tiny connectors, resistors, and semiconductor components with micron-level precision.

- Automotive: Sorting and orienting screws, gaskets, and engine parts for assembly lines.

- Medical Devices: Handling sterile components like syringes, implants, and micro-needles in contamination-free environments.

- Aerospace: Ensuring reliable part feeding for high-precision aerospace fasteners and components.

- Food & Pharmaceuticals: Meeting strict hygiene standards for sorting tablets, capsules, and packaging components.

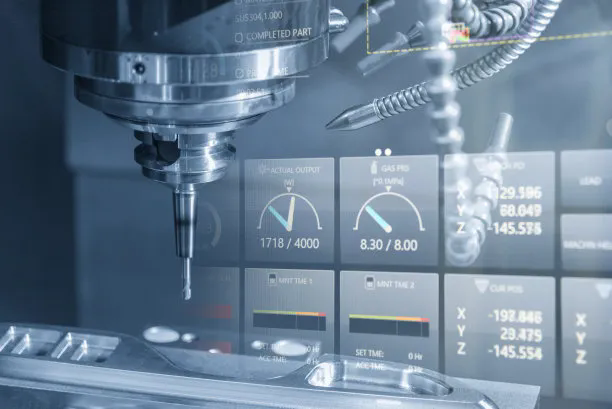

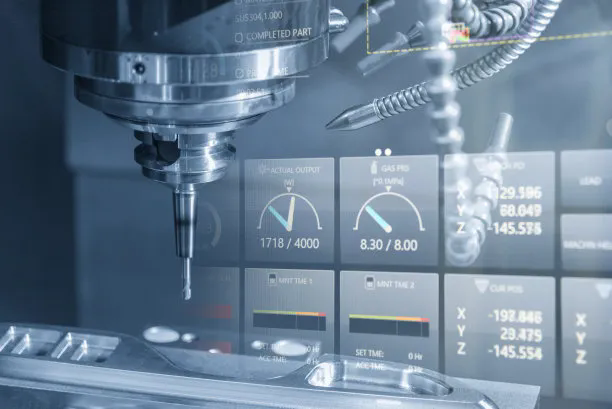

Our Stainless Steel Vibrating Discs Factory & Equipment

Located in Dongguan, China, our 2,000 sqm facility is equipped with:

-

5-axis & 4-axis CNC machining centers

-

Swiss-type CNC lathes

-

Precision grinding & EDM machines

-

Stamping & die-casting units

Our team of 20+ years of experienced engineers ensures every project meets the highest industry benchmarks.

Competitive Advantages in Stainless Steel Vibrating Discs

✅ Tolerances as tight as ±0.02mm

✅ Fast prototyping & low MOQ (10 pieces)

✅ One-stop machining & finishing services

✅ Strict quality assurance with full traceability

✅ Competitive pricing & on-time delivery

FAQ

Q1: Where can I get product & price information?

A1: Send us an inquiry e-mail, we will contact you once we received your mail.

Q2: How long will I get the sample?

A2: Depends on your specific items, within 3-7 days generally.

Q3: What kinds of information do you need for a quote?

A3: Kindly please provide the product drawings in PDF, if provide in STEP or IGS will be better.

Q4: What are the payment terms?

A4: We accept 50% as a payment deposit, when the goods are prepared, we shoot photos or videos for your check, and then you can pay the balance. For small quantities, we accept Paypal, the commission will be added to the order. For big amounts, T/T is preferred.

Q5: How to deliver the goods?

A5: We deliver the products by courier company.

Q6: Are you a trading company or factory?

A6: We are factory direct with 17 experienced engineers and more than 50 employees as well approximate 3,000m2 workshop area.

Q7: What shall we do if we don’t have drawings?

A7: Please send your sample to our factory, then we can copy and provide you better solutions. If send us pictures or drafts with dimensions(Length, Height, Width), CAD or 3D file will be made for you.

Q8: Can we get some samples before mass production?

A8: Absolutely yes.

Q9: Will my drawings be safe after sending them to you?

A9: Yes, we will keep them well and won’t release them to the third party without your permission.

Q10: Is it possible to know the operation status of my products without visiting your company?

A10: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.

Q11: If you make poor quality goods, will you refund?

A11: In fact, we won’t take risks to produce poor-quality products. Meanwhile, we manufacture good quality products till you are satisfied plastic machining.

Partner With Us

“Your design vision, our engineering precision – let’s create something extraordinary.”

Request a Free Project Review

📧 Email: ganyuan1688@gmail.com

🌐 Website: ganyuan1688@gmail.com

📞 Tel: 86–13929256361

Dongguan Ganyuan Hardware Technology Co., Ltd.

Request a Free Quote Today!

📩 Send your drawings (PDF/STEP/IGS) for instant pricing

📞 Discuss your project with our engineering team