Product Categories

- Brass Parts (11)

- Plastic Parts (14)

- Aluminum alloy products/accessories (86)

- Precision Machinery Parts (179)

- Watch/Jewelry Accessories (5)

- Stainless Steel Products/Accessories (140)

- cnc turning parts (121)

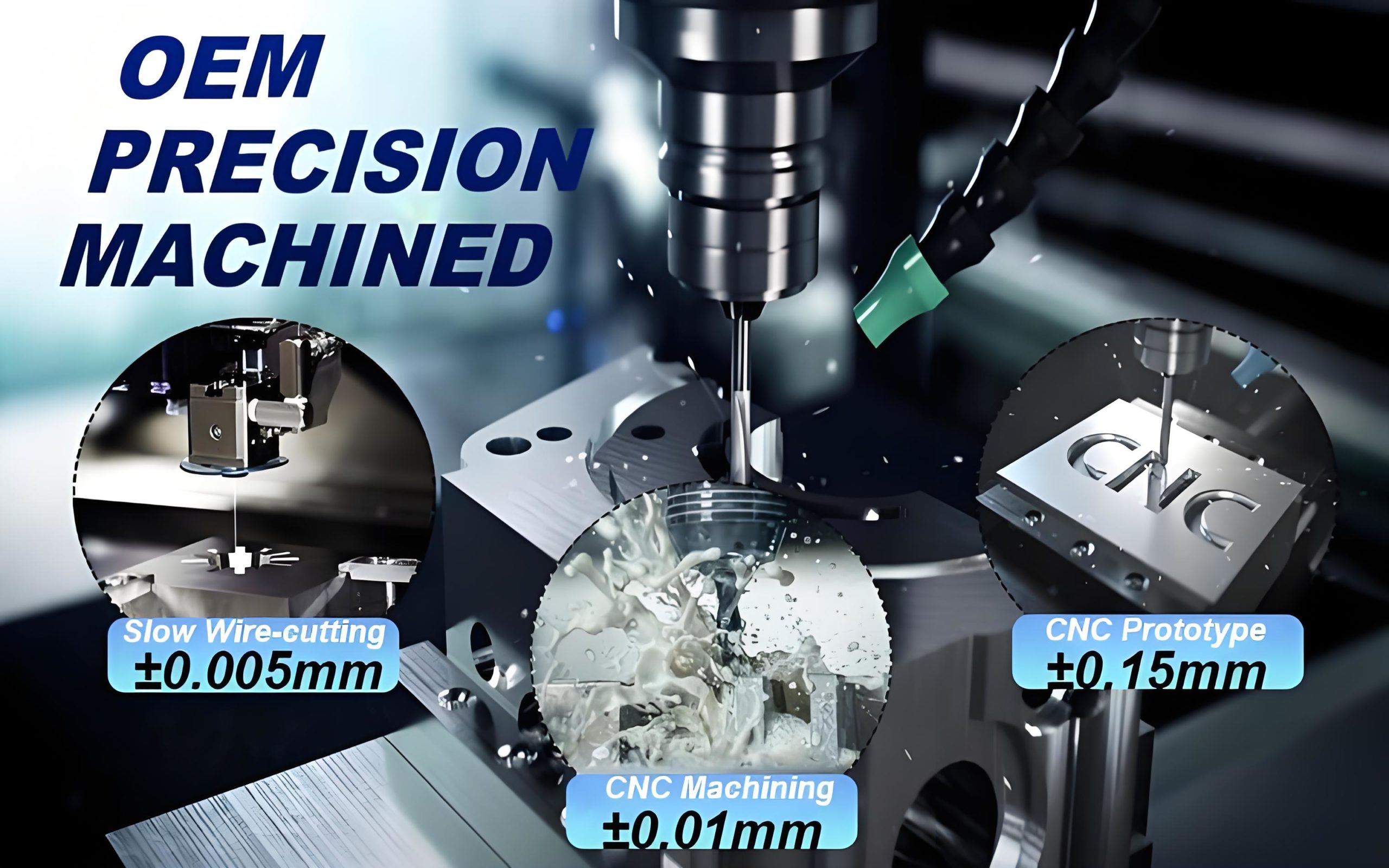

At Ganyuan, we specialize in CNC machining of precision stainless steel shafts that meet the most rigorous industry standards. Our advanced manufacturing capabilities allow us to produce shafts with tolerances as tight as ±0.01mm, ensuring perfect fit and function in critical applications.

| Production type | Custom production and processing | Material | Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting,cnc machined components |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | Dongguan, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts; Machining parts;stainless steel shafts |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

1. Superior Material Properties

Excellent corrosion resistance

High strength-to-weight ratio

Good wear characteristics

Maintains properties in extreme temperatures

2. Precision Machining Capabilities

CNC turning with live tooling

Centerless grinding for precision diameters

Thread rolling and grinding

Keyway and spline machining

3. Quality Assurance

100% material certification

In-process dimensional checks

Final inspection with CMM

Surface roughness verification

Hardness testing

Material Selection: Certified stainless steel bars

Rough Machining: Turning to near-net shape

Heat Treatment: Solution treatment/aging for PH alloys

Finish Machining: Precision grinding to final dimensions

Surface Enhancement:

Electropolishing

Passivation

TiN coating

We are a manufacturer integrating industry and trade. We have more than 20 years of experience in production technology. We are located in Dongguan City, Guangdong Province, China. We have advanced high-end professional production and processing technology, and are committed to innovative R&D and production. After years of market tempering and exploration, it has high-quality technical management personnel, experienced designers, R&D personnel and a perfect company management system Custom shaft machining.

Our factory has a plant area of about 2,000 square meters and masters core processing technologies. It has high-end precision production equipment: CNC lathes, 5-axis CNC, 4-axis CNC, stamping equipment, die-casting equipment, etc.

Auxiliary production equipment: electroplating, anodizing, hard anodizing and surface treatment.

We have complete testing equipment: sophisticated three-dimensional testing, two-dimensional testing, hardness tester, height meter, projector and other conventional testing equipment.

If you are interested in our products, please contact me and I will provide the best price support and quality service Custom shaft machining.

I believe we will establish a good and long-term cooperation.

Welcome to send pictures and letters to discuss, thank you!

20+ Years of shaft manufacturing experience

5-Axis CNC machines for complex geometries

In-House Grinding capabilities

Complete Metrology Lab with CMM and optical comparators

Quick-Turn Prototyping (5-7 days)

High-Volume Production capacity

For surface treatment, our suppliers have been working with us for many years. They have rich experience and are familiar with all the quality requirements of each other. The quality is stable and more guaranteed. Such as: heat treatment, spray painting, powder coating, blackening, silver/gold plating, electrolytic polishing, nitriding, phosphating, nickel/zinc/chromium/TiCN plating, anodizing, polishing, passivation, sandblasting, galvanizing, heat treatment , hardening, laser marking, etc. according to customer requirements.

Q: What stainless steel grades do you recommend for shafts?

A: 304 for general use, 316 for corrosive environments, 17-4PH for high strength.

Q: Can you produce hollow stainless steel shafts?

A: Yes, we machine hollow shafts with wall thickness down to 1mm.

Q: What surface treatments are available?

A: Electropolishing, passivation, hard chrome plating, and various coatings.

Q: How do you ensure shaft straightness?

A: Through stress-relieving processes and precision centerless grinding.

Q: What’s your lead time for custom shafts?

A: Prototypes in 7-10 days, production orders in 15-20 days.

Contact Our Shaft Specialists Today

📧 Email: ganyuan1688@gmail.com

🌐 Website: ganyuan1688@gmail.com

📞 Tel: 86–13929256361

Why Partner With Us for Your Stainless Steel Shaft Needs?

→ Precision Manufacturing with ±0.01mm tolerance

→ Material Expertise in all stainless steel grades

→ Complete In-House machining and finishing

→ Quick-Turn prototyping and production

→ Technical Support throughout your project

Elevate Your Machinery with Our Precision Stainless Steel Shafts!