Product Description

| Production type |

Custom production and processing |

Material |

Metal,plastic machining, carbon steel, stainless steel, copper, aluminum alloy,plastic machining |

| Processing methods |

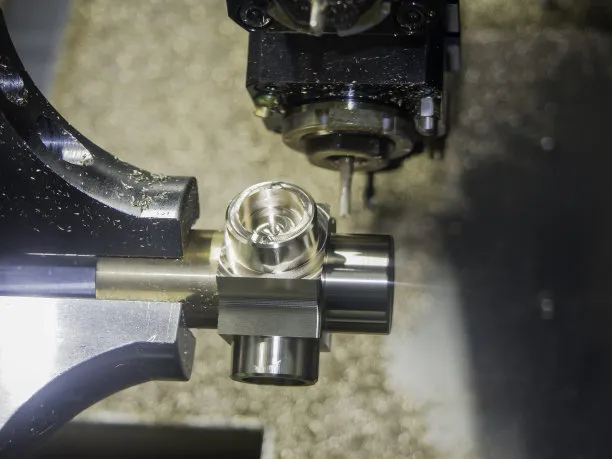

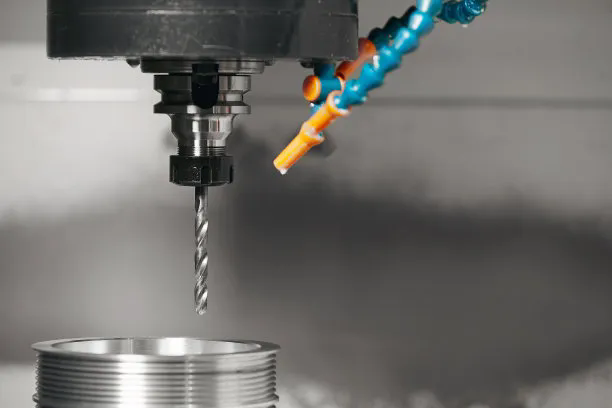

CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting |

Processing Equipment |

CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting |

| Accuracy |

±0.02mm |

Whether proofing |

yes |

| Is it customized |

yes |

Proofing time |

7-15 days |

| OEM/ODM |

OEM ODM CNC machining service |

surface treatment |

Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin |

Dongguan, China |

Quotations |

FOB |

| Business Type: |

Manufacturer/Factory & Trading Company |

Main Products: |

CNC parts; Machining parts;stainless steel shaft |

| Management System Certification: |

ISO 9001:2015 |

Average Lead Time: |

Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

The corrosion resistance of Stainless steel shaft for durability and reliability. High-quality construction,Superior quality and performance,ideal for various applications,Choose quality. is its hallmark property. Under severe environmental conditions such as humidity, acid and alkali, stainless steel can exhibit excellent corrosion resistance.

Stainless steel shaft for durability and reliability. High-quality construction,Superior quality and performance,ideal for various applications,Choose quality.

In the food processing industry, equipment parts that are frequently in contact with various food raw materials, processing aids, and cleaning and disinfection solutions, such as the stirring paddles of food mixers, conveying pipes, etc., stainless steel parts can maintain their original performance and appearance for a long time, effectively preventing the dissolution of metal ions caused by corrosion, avoiding adverse effects on food quality, and ensuring strict implementation of food safety and hygiene standards.

In the field of marine engineering, such as the shell of a ship, the internal components of seawater desalination equipment, etc., stainless steel parts can resist the long-term erosion of seawater, greatly prolonging the service life of the equipment, reducing the maintenance cost and downtime caused by corrosion, and providing a reliable material foundation for the development and utilization of marine resources.

We are a manufacturer integrating industry and trade. We have more than 20 years of experience in production technology. We are located in Dongguan City, Guangdong Province, China. We have advanced high-end professional production and processing technology, and are committed to innovative R&D and production. After years of market tempering and exploration, it has high-quality technical management personnel, experienced designers, R&D personnel and a perfect company management system stainless steel shaft.

stainless steel shaft

stainless steel shaft

Our factory has a plant area of about 2,000 square meters and masters core processing technologies. It has high-end precision production equipment: CNC lathes, 5-axis CNC, 4-axis CNC, stamping equipment, die-casting equipment, etc.

Our Adrantages

We cooperate with many high-quality material suppliers, and the quality is very guaranteed. Please feel free to choose our materials. At the same time, supporting documents can be provided for all materials. Materials are available, such as aluminum alloy, steel alloy, carbon steel, stainless steel, copper, brass, titanium alloy, bronze, nylon,plastic machining, etc. Aluminum 6061/6063/7075; Iron 1215/45/1045; Stainless steel 303/304/316; Copper; Brass; Bronze (H59/H62/T2/H65); Plastic POM/PE/PSU/PA/PEEK, etc. can be based on Customer requirements.

surface treatment

For surface treatment, our suppliers have been working with us for many years. They have rich experience and are familiar with all the quality requirements of each other. The quality is stable and more guaranteed. Such as: heat treatment, spray painting, powder coating, blackening, silver/gold plating, electrolytic polishing, nitriding, phosphating, nickel/zinc/chromium/TiCN plating, anodizing, polishing, passivation, sandblasting, galvanizing, heat treatment , hardening, laser marking, etc. according to customer requirements.

FAQ

Q1: Where can I get product & price information? A1: Send us an inquiry e-mail, we will contact you once we received your mail.

Q2: How long will I get the sample? A2: Depends on your specific items, within 3-7 days generally.

Q3: What kinds of information do you need for a quote? A3: Kindly please provide the product drawings in PDF, if provide in STEP or IGS will be better.

Q4: What are the payment terms? A4: We accept 50% as a payment deposit, when the goods are prepared, we shoot photos or videos for your check, and then you can pay the balance. For small quantities, we accept Paypal, the commission will be added to the order. For big amounts, T/T is preferred.

Q5: How to deliver the goods? A5: We deliver the products by courier company.

Q6: Are you a trading company or factory? A6: We are factory direct with 17 experienced engineers and more than 50 employees as well approximate 3,000m2 workshop area.

Q7: What shall we do if we don’t have drawings? A7: Please send your sample to our factory, then we can copy and provide you better solutions. If send us pictures or drafts with dimensions(Length, Height, Width), CAD or 3D file will be made for you.

Q8: Can we get some samples before mass production? A8: Absolutely yes.

Q9: Will my drawings be safe after sending them to you? A9: Yes, we will keep them well and won’t release them to the third party without your permission.

Q10: Is it possible to know the operation status of my products without visiting your company? A10: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.

Q11: If you make poor quality goods, will you refund? A11: In fact, we won’t take risks to produce poor-quality products. Meanwhile, we manufacture good quality products till you are satisfied plastic machining.

Packaging Details 1. Commercial packaging: 1pc/plastic bag + color box +carton + pallet; 2. Industrial packaging: (1). plastic tube + carton + pallet; (2). plastic bag + kraft paper + carton + pallet; 3. According to the requirement of customer.