Product Categories

- Brass Parts (11)

- Plastic Parts (14)

- Aluminum alloy products/accessories (86)

- Precision Machinery Parts (179)

- Watch/Jewelry Accessories (5)

- Stainless Steel Products/Accessories (140)

- cnc turning parts (121)

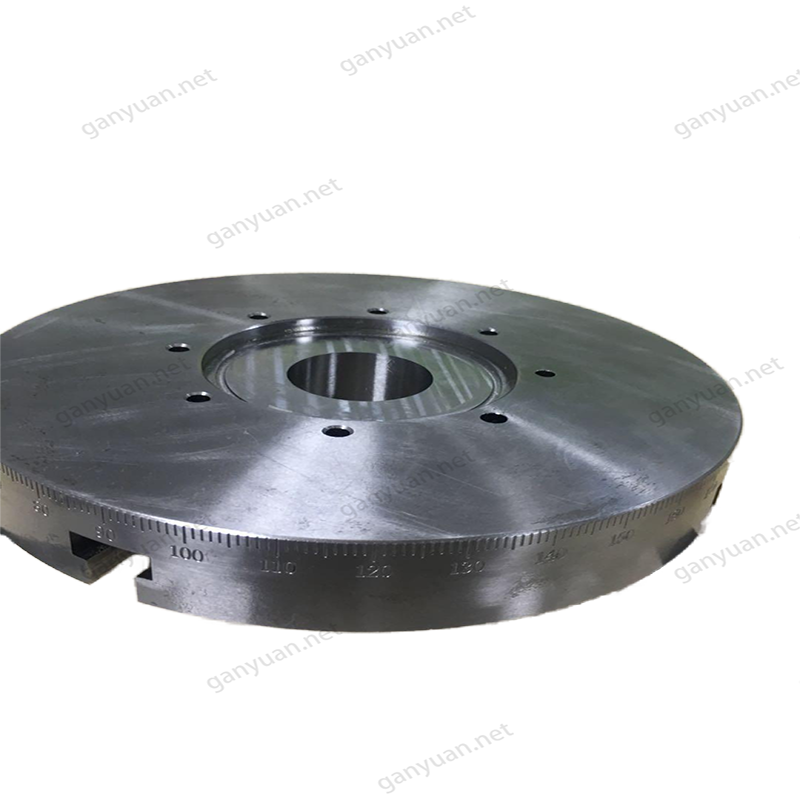

Our Stainless Steel Flange Dial is a high-precision measurement component manufactured from grade 304/316 stainless steel through advanced CNC turning and milling processes. Designed for industrial instrumentation and control systems, it delivers exceptional corrosion resistance and long-term dimensional stability.

| Feature | Specification |

|---|---|

| Material | 304/316 Stainless Steel (ASTM A276 compliant) |

| Manufacturing Process | CNC Turning + Precision Milling |

| Tolerance | ±0.01mm (critical surfaces) |

| Surface Finish | Ra 0.4μm (mirror polish optional) |

| Flange Types | Slip-on, Weld Neck, Threaded (customizable) |

| Diameter Range | 20mm–300mm (standard) |

| Marking Options | Laser engraving, etched graduations |

✔ Ultra-Precise Machining

4-axis CNC milling ensures perfect concentricity

Micro-graduation engraving with ≤0.05° angular accuracy

✔ Premium Material Properties

316L variant available for marine/chemical environments

Passivation treatment standard on all units

✔ Customization Ready

Custom bore sizes and bolt circle patterns

Optional luminescent markings for low-light visibility

✔ Rigorous Quality Control

100% CMM inspection for flatness and runout

Salt spray tested per ASTM B117 (500+ hours)

Precision saw cutting of stainless steel billets

Stress-relief annealing when required

Turning: Achieves IT6 grade dimensional accuracy

Milling: 4-axis contouring for complex flange features

Electrolytic polishing for Ra 0.2μm super-finish

Bead blasting for matte aesthetic (upon request)

Laser scanning for profile verification

Torque testing on threaded variants

20+ Years of precision Stainless Steel Flange Dial manufacturing

ISO 9001:2015 certified production

DFM Support for custom requirements

Fast-Turn Prototyping (5-7 working days)

If you are interested in our products, please contact me and I will provide the best price support and quality service.Stainless Steel Flange Dial

I believe we will establish a good and long-term cooperation.

Welcome to send pictures and letters to discuss, thank you!

Hard anodizing (up to 50μm)

Electroless nickel plating

Passivation for stainless steel

Bead blasting for uniform matte finish

PVD coatings for wear resistance

Premium Packaging: Anti-static bags + Foam protection + Gift box options

OEM/ODM Services: Provide samples or drawings (PDF/STEP/IGS formats accepted)

Global Shipping: DHL/FedEx/Sea freight supported