In the era of advanced manufacturing, plastic parts machining has become a cornerstone of innovation, enabling lightweight, durable, and cost-effective components for diverse industries. Dongguan Ganyuan Hardware Technology Co., Ltd. specializes in delivering high-precision plastic machining solutions that transform your designs into reality—combining state-of-the-art CNC technology, material expertise, and factory-direct efficiency to meet the most demanding project requirements.

Product Description

| Production type |

Custom production and processing |

Material |

Metal,plastic machining, carbon steel, stainless steel, copper, aluminum alloy,plastic machining |

| Processing methods |

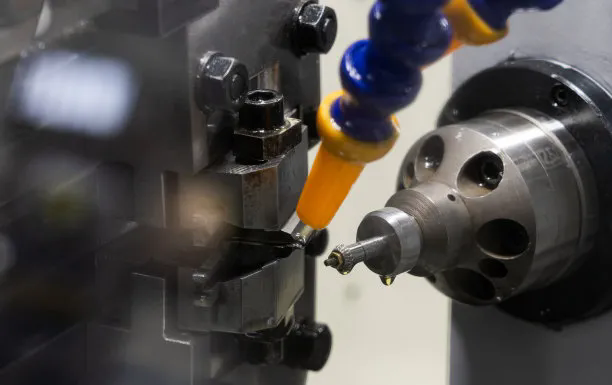

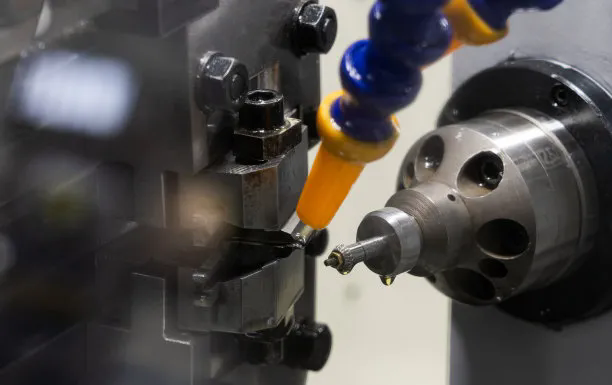

CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting |

Processing EquipmentCustom Precision CNC Parts |

5 Axis CNC Machining, grinder, wire cutting |

| Accuracy |

±0.02mm |

Whether proofing |

yes |

| Is it customized |

yes |

Proofing time |

7-15 days |

| OEM/ODM |

OEM ODM CNC machining service |

surface treatment |

Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin |

Dongguan, China |

Quotations |

FOB |

| Business Type: |

Manufacturer/Factory & Trading Company |

Main Products: |

CNC parts; Machining parts;plastic parts machining |

| Management System Certification: |

ISO 9001:2015 |

Average Lead Time: |

Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

With over 20 years of experience, we excel in crafting custom plastic parts machining with precision and consistency. Our capabilities span:

Trust our plastic parts machining for outstanding results. We focus on details to provide parts that fit your specifications perfectly.

We work with a wide range of engineering plastics, including:

- High-Strength Polymers: POM, PA (Nylon), ABS, PC, and glass-filled composites for components requiring rigidity and impact resistance.

- Specialized Materials: PEEK, PPS, and anti-static/conductive plastics for high-temperature, chemical-resistant, or electrical applications.

- Food-Grade & Medical-Grade Plastics: FDA/ROHS-compliant materials for hygiene-sensitive industries like pharmaceuticals and consumer goods.

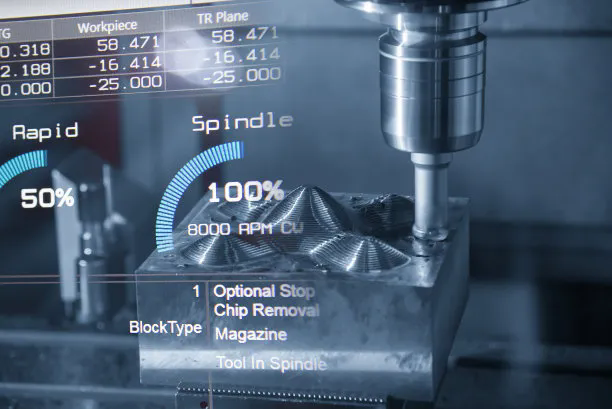

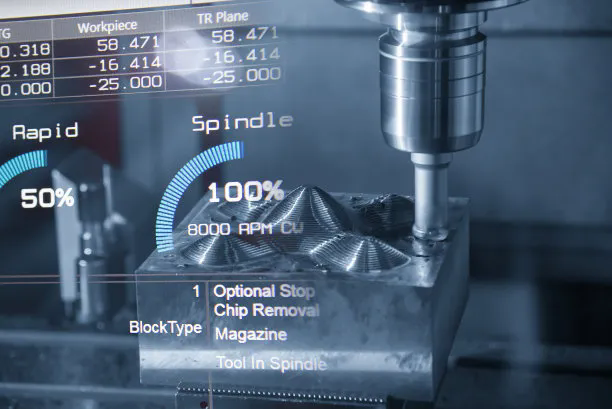

Leveraging our ISO 9001:2015 certified facility, we utilize advanced equipment to achieve:

- ±0.02mm Tolerance: 5-axis CNC machining for complex geometries, such as intricate gears, contoured handles, or micro-components (down to 2mm in diameter).

- Surface Roughness Ra 1.6: Grinding, EDM wire cutting, and laser finishing for smooth, visually appealing surfaces ideal for optical components or high-end consumer products.

- Rapid Prototyping: Turn concepts into functional samples in 7–15 days using CNC machining or 3D printing, minimizing design iteration time.

From initial design to final assembly, we offer full customization:

- Design Support: Convert STEP, IGES, PDF, or even hand-drawn sketches into optimized 3D models, with DFM (Design for Manufacturing) feedback to enhance producibility.

- Surface Treatments: Electroplating, oxidation, UV coating, or rubber overmolding to improve aesthetics, functionality, and environmental resistance.

- Assembly Solutions: Integrate metal inserts, hinges, or multi-material components for complex assemblies, ensuring seamless compatibility.

Manufacturing Process

-

Material Certification

-

Precision Machining

-

Heat Treatment

-

Quality Validation

Why Choose Us for plastic parts machining?

- No Middleman Markups: Competitive pricing with MOQ as low as 50 pieces, ideal for both prototyping and mass production (up to 10,000+ units).

- Fast Turnaround: 12–15 working days for standard orders, including surface treatment and quality inspection.

- ISO 9001:2015 Compliance: Stringent QC processes, including First Article Inspection (FAI), in-process dimensional checks, and final material certification (mill test reports available).

- Traceability: Full documentation of material sources, machining parameters, and testing results for critical applications.

- Micro-Machining Expertise: Swiss-type CNC lathes for components as small as 2mm, perfect for miniature gears, connectors, and precision instruments.

- Complex Geometry Mastery: 5-axis milling for helical threads, internal splines, and multi-angle contours that traditional machining cannot achieve.

- Multilingual Team: Responsive customer service in English and Chinese, with quick turnaround on quotes (24–48 hours with detailed drawings).

- Transparent Communication: Weekly production updates with photos/videos, ensuring you monitor progress from machining to packaging (FOB Dongguan, flexible shipping options).

FAQ

A1: We accept STEP, IGES, Parasolid (3D), and PDF/DWG (2D drawings). If you have a physical sample or sketch, our engineers can create a CAD model for you.

A2: Yes! Our 5-axis CNC machines achieve ≤0.01° angular accuracy for ratchet teeth, bevel gears, and other precision components.

A3: Options include nickel plating, chrome plating, anodizing (for composite materials), texture embossing, and anti-slip coatings for ergonomic handles.

A4: We optimize cutting parameters (speed, feed rate, cooling) and select materials with high dimensional stability (e.g., POM, reinforced nylon) to minimize thermal distortion.

A5: Yes—we provide commercial packaging (color boxes, pallets) or industrial solutions (plastic tubes, anti-static bags), tailored to your logistics needs.

Whether you need a single prototype or thousands of production parts, Ganyuan’s plastic parts machining services deliver the accuracy, durability, and cost efficiency your project demands.

✅

Start Your Project Today:

📧

Email: ganyuan1688@gmail.com (attach your design files for an instant quote)

📞

Phone/WhatsApp: +86 139 2925 6361 (discuss technical details with our engineers)

🌐

Online Quote:

https://www.ganyuan.net (submit your requirements via our quick quote form)

Dongguan Ganyuan Hardware Technology Co., Ltd.

📍 Factory Address: 1st Floor, Building A, No. 78, Yintong Road, Shuikou Industrial Zone, Dalang Town, Dongguan City, Guangdong Province, China

🏭 Facility: 2,000m² | 5-Axis CNC Machining Center

✅ Request a Free Design Consultation: Let our team help optimize your design for manufacturability, ensuring the best balance of performance and cost.

At Ganyuan, we don’t just machine plastic parts—we engineer solutions that drive innovation. Partner with us, and experience the difference of precision machining combined with 20+ years of industrial expertise.