Product Categories

- Brass Parts (11)

- Plastic Parts (20)

- Aluminum alloy products/accessories (104)

- Precision Machinery Parts (205)

- Watch/Jewelry Accessories (6)

- Stainless Steel Products/Accessories (171)

- cnc turning parts (123)

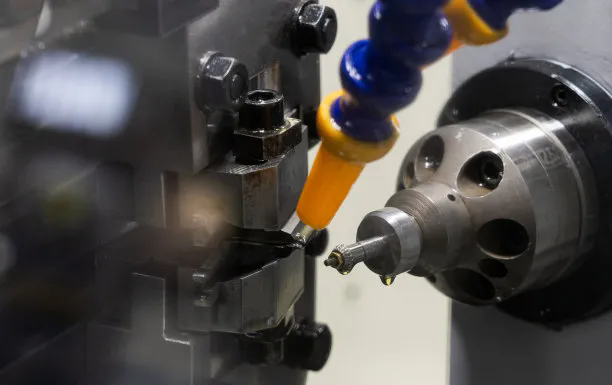

The Mask shaft is a critical component in gear and transmission manufacturing, ensuring smooth power transfer, high precision, and long-term durability. At Ganyuan, we specialize in advanced CNC Mask shaft production, utilizing cutting-edge technology to meet the stringent demands of industries such as automotive, aerospace, medical equipment, and electronic communications.

| Production type | Custom production and processing | Material | Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC Machining Parts, grinder, wire cutting,cnc machined components |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | Dongguan, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts; Machining parts;Mask shaft |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

With over 20 years of expertise in precision machining, Ganyuan has established itself as a leader in custom Mask shaft manufacturing. Our advanced 5-axis and 4-axis CNC machines, combined with rigorous quality control, guarantee unmatched accuracy and performance.

High Precision: Tight tolerances (up to ±0.005mm) for seamless gear engagement.

Superior Durability: Made from high-grade materials like stainless steel, alloy steel, and titanium.

Customization: Tailored designs based on client specifications (samples or drawings).

Advanced Surface Treatments: Hardening, nitriding, anodizing, and plating for enhanced wear resistance.

Our CNC lathes and milling machines ensure ultra-precise shaping of hobbing shafts, maintaining consistency across high-volume production runs.

We use premium materials, including:

Aluminum alloys (6061, 7075) for lightweight applications

Stainless steel (303, 304, 316) for corrosion resistance

Carbon steel & alloy steel for high-strength requirements

Brass, bronze, and titanium for specialized industrial uses

Every Mask shaft undergoes strict inspection using:

3D measuring instruments

Hardness testers & projectors

Dimensional accuracy checks

Gearboxes, differential systems, and powertrain components

High-torque, lightweight shafts for aircraft and UAVs

Precision-machined shafts for surgical robots and imaging devices

Miniaturized, high-tolerance components for communication devices

✅ 20+ Years of Expertise – Trusted by global clients for precision engineering

✅ End-to-End Customization – From prototyping to mass production

✅ Fast Turnaround & Competitive Pricing – Efficient production with cost-saving solutions

✅ Comprehensive Surface Finishing – Enhanced corrosion & wear resistance

“Your design vision, our engineering precision – let’s create something extraordinary.”

Request a Free Project Review

📧 Email: ganyuan1688@gmail.com

🌐 Website: ganyuan1688@gmail.com

📞 Tel: 86–13929256361

Dongguan Ganyuan Hardware Technology Co., Ltd.