Product Categories

- Brass Parts (10)

- Plastic Parts (12)

- Aluminum alloy products/accessories (83)

- Precision Machinery Parts (172)

- Watch/Jewelry Accessories (5)

- Stainless Steel Products/Accessories (132)

- cnc turning parts (121)

We are seeking suppliers for five-axis CNC machining plant machinery parts. Our company, Dongguan Ganyuan Hardware Technology Co., Ltd., specializes in manufacturing and supplying customized machine parts. With our precision machining services, we provide a wide range of industrial machine parts, including aluminum and steel components. Our expertise extends to automotive, aerospace, and electronic components, as well as plastic injection molding services. We offer contract manufacturing services and integrated solutions for all your industrial equipment part needs. Contact us for high-quality, 3D printed machine parts and reliable fabrication of metal components.

| Production type | Custom production and processing | Material | Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting,cnc machined components |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | Dongguan, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts; Machining parts;custom metal stampings |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

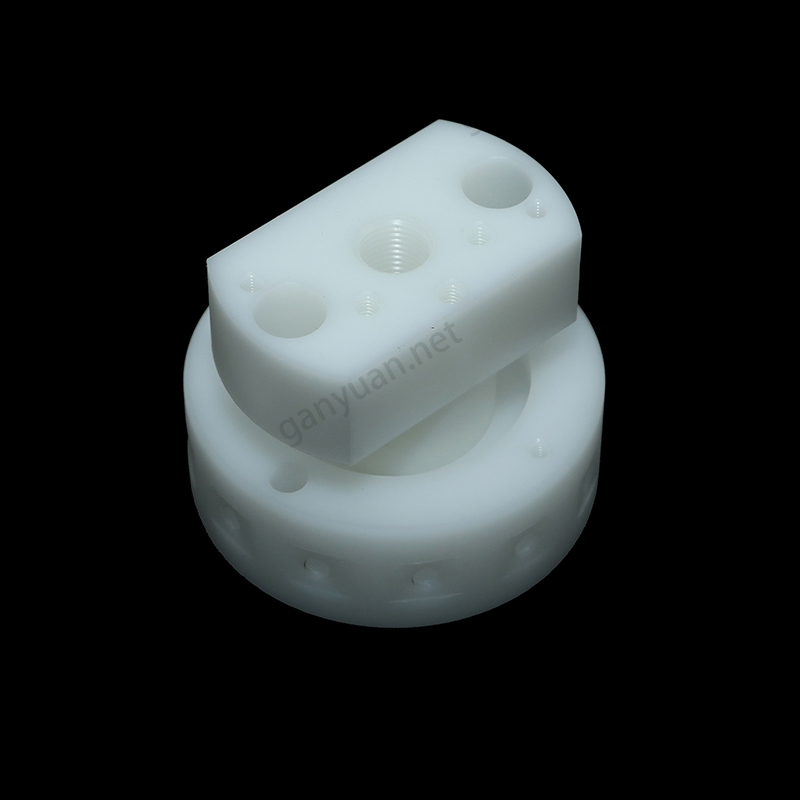

Precision CNC machined plastic parts, made of POM with a surface roughness of Ra 1.6.

Machined plastic: Precision crafted for durability and versatility, ideal for various applications.

For custom CNC machined plastic parts, the minimum order quantity is 50 pieces and the delivery time is 12 days.

Ganyuan has produced many similar CNC machined plastic electronic accessories. If you have any questions about precision custom CNC machined plastic parts, please contact us immediately. Ganyuan will be your wise choice.

We are a manufacturer integrating industry and trade. We have more than 20 years of experience in production technology. We are located in Dongguan City, Guangdong Province, China. We have advanced high-end professional production and processing technology, and are committed to innovative R&D and production. After years of market tempering and exploration, it has high-quality technical management personnel, experienced designers, R&D personnel and a perfect company management system custom metal stampings.

Our factory has a plant area of about 2,000 square meters and masters core processing technologies. It has high-end precision production equipment: CNC lathes, 5-axis CNC, 4-axis CNC, stamping equipment, die-casting equipment, etc.

Auxiliary production equipment: electroplating, anodizing, hard anodizing and surface treatment.

We have complete testing equipment: sophisticated three-dimensional testing, two-dimensional testing, hardness tester, height meter, projector and other conventional testing equipment.

If you are interested in our products, please contact me and I will provide the best price support and quality service custom metal stampings.

I believe we will establish a good and long-term cooperation.

Welcome to send pictures and letters to discuss, thank you!

We cooperate with many high-quality material suppliers, and the quality is very guaranteed. Please feel free to choose our materials. At the same time, supporting documents can be provided for all materials. Materials are available, such as aluminum alloy, steel alloy, carbon steel, stainless steel, copper, brass, titanium alloy, bronze, nylon, acrylic, cnc machined components,etc.

Aluminum 6061/6063/7075; Iron 1215/45/1045; Stainless steel 303/304/316; Copper; Brass; Bronze (H59/H62/T2/H65); Plastic POM/PE/PSU/PA/PEEK, etc. can be based on Customer requirements.

For surface treatment, our suppliers have been working with us for many years. They have rich experience and are familiar with all the quality requirements of each other. The quality is stable and more guaranteed. Such as: heat treatment, spray painting, powder coating, blackening, silver/gold plating, electrolytic polishing, nitriding, phosphating, nickel/zinc/chromium/TiCN plating, anodizing, polishing, passivation, sandblasting, galvanizing, heat treatment , hardening, laser marking, etc. according to customer requirements.