Product Categories

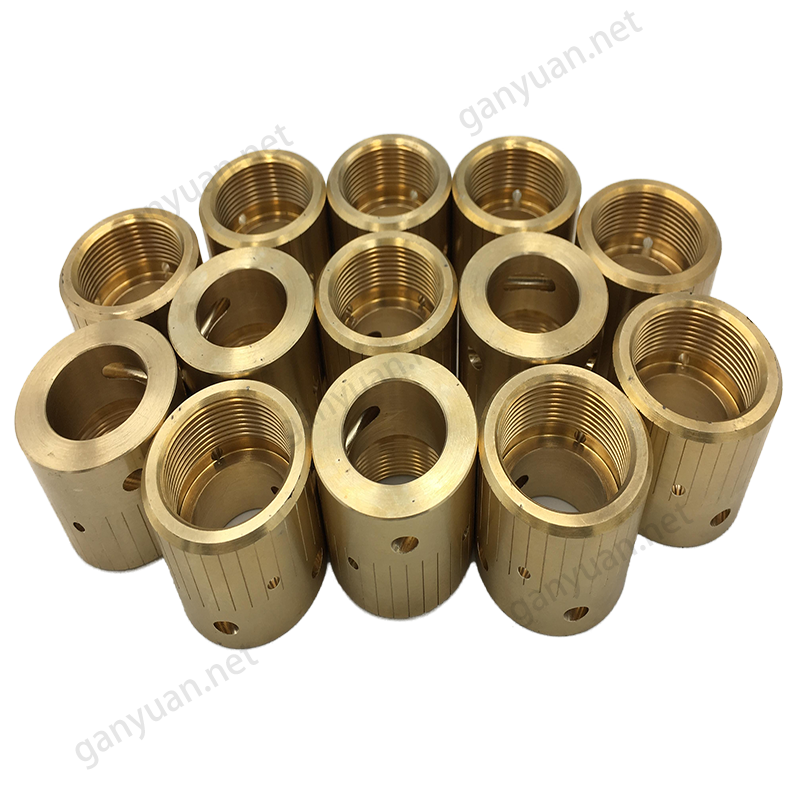

- Brass Parts (9)

- Plastic Parts (12)

- Aluminum alloy products/accessories (79)

- Precision Machinery Parts (166)

- Watch/Jewelry Accessories (5)

- Stainless Steel Products/Accessories (126)

- cnc turning parts (121)

Product Description

Custom aluminum parts: Lightweight yet durable, crafted to your exact specifications for optimal performance and style.

Detailed PhotosMask machine knurling wheel: It is processed into a rough blank by CNC turning, and then processed by precision 5-axis CNC, and then surface electroplating is completed.

We are a manufacturer integrating industry and trade. We have more than 20 years of experience in production technology. We are located in Dongguan City, Guangdong Province, China. We have advanced high-end professional production and processing technology, and are committed to innovative R&D and production. After years of market tempering and exploration, it has high-quality technical management personnel, experienced designers, R&D personnel and a perfect company management system.

Our factory has a plant area of about 2,000 square meters and masters core processing technologies. It has high-end precision production equipment: CNC lathes, 5-axis CNC, 4-axis CNC, stamping equipment, Custom aluminum parts, etc.

Auxiliary production equipment: electroplating, anodizing, hard anodizing and surface treatment.

We have complete testing equipment: sophisticated three-dimensional testing, two-dimensional testing, hardness tester, height meter, projector and other conventional testing equipment.

If you are interested in our products, please contact me and I will provide the best price support and quality service.

I believe we will establish a good and long-term cooperation.

Welcome to send pictures and letters to discuss, thank you!

FAQ

Q1: Where can I get product & price information?

A1: Send us an inquiry e-mail, we will contact you once we received your mail.

Q2: How long will I get the sample?

A2: Depends on your specific items, within 3-7 days generally.Custom aluminum parts

Q3: What kinds of information do you need for a quote?

A3: Kindly please provide the product drawings in PDF, if provide in STEP or IGS will be better.

Q4: What are the payment terms?

A4: We accept 50% as a payment deposit, when the goods are prepared, we shoot photos or videos for your check, and then you can

pay the balance. For small quantities, we accept Paypal, the commission will be added to the order. For big amounts, T/T is

preferred.

Q5: How to deliver the goods?

A5: We deliver the products by courier company.

Q6: Are you a trading company or factory?

A6: We are factory direct with 17 experienced engineers and more than 50 employees as well approximate 3,000m2 workshop area.

Q7: What shall we do if we don’t have drawings?

A7: Please send your sample to our factory, then we can copy and provide you better solutions. If send us pictures or drafts with

dimensions(Length, Height, Width), CAD or 3D file will be made for you.Custom aluminum parts

Q8: Can we get some samples before mass production?

A8: Absolutely yes.

Q9: Will my drawings be safe after sending them to you?

A9: Yes, we will keep them well and won’t release them to the third party without your permission.

Q10: Is it possible to know the operation status of my products without visiting your company?

A10: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the

machining progress.

Q11: If you make poor quality goods, will you refund?

A11: In fact, we won’t take risks to produce poor-quality products. Meanwhile, we manufacture good quality products till you are

satisfied.