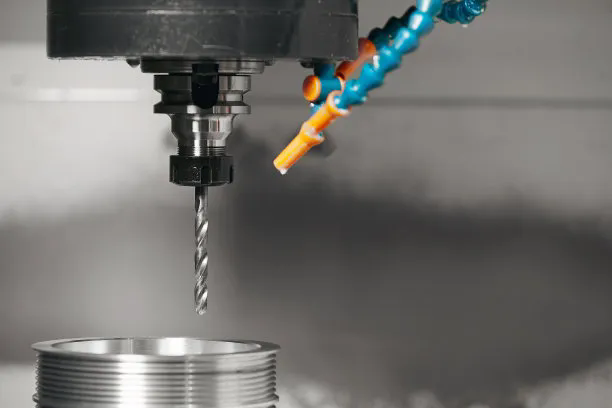

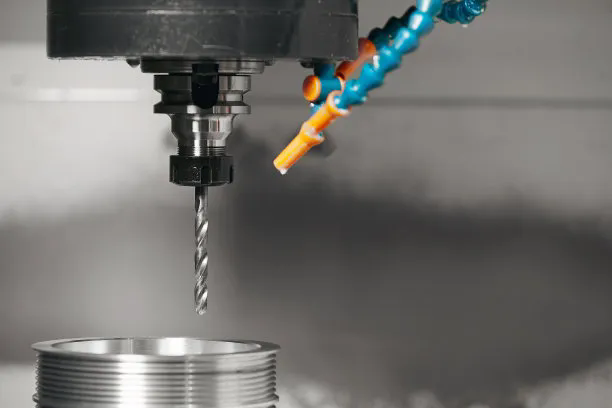

In industries where strength, durability, and weight optimization are critical, CNC titanium machining emerges as the gold standard for crafting high-performance components. Dongguan Ganyuan Hardware Technology Co., Ltd. specializes in leveraging advanced CNC technology to transform titanium alloys into precision parts that excel in extreme environments—combining lightweight design, superior corrosion resistance, and unmatched mechanical strength for applications ranging from aerospace to medical devices.

Product Description

| Production type |

Custom production and processing |

Material |

Metal,plastic machining, carbon steel, stainless steel, copper, aluminum alloy,plastic machining |

| Processing methods |

CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting |

Processing Equipment |

CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting |

| Accuracy |

±0.02mm |

Whether proofing |

yes |

| Is it customized |

yes |

Proofing time |

7-15 days |

| OEM/ODM |

OEM ODM CNC machining service |

surface treatment |

Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin |

Dongguan, China |

Quotations |

FOB |

| Business Type: |

Manufacturer/Factory & Trading Company |

Main Products: |

CNC parts; Machining parts;CNC titanium machining |

| Management System Certification: |

ISO 9001:2015 |

Average Lead Time: |

Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

The Titanium Advantage: Material Excellence for Demanding Fields

Titanium and its alloys (e.g., Ti-6Al-4V, Ti-5Al-2.5Sn) are prized for:

- Exceptional Strength-to-Weight Ratio: Up to 40% lighter than steel while maintaining comparable strength, ideal for applications where weight reduction directly impacts efficiency (e.g., aircraft components, racing car parts).

- Corrosion Resistance: Naturally resistant to rust, seawater, and harsh chemicals, making it perfect for marine, medical, and aerospace environments.

- High-Temperature Stability: Retains mechanical properties at temperatures up to 500°C, ensuring reliability in engine compartments or industrial furnaces.

Our CNC titanium machining services harness these properties to deliver parts with ±0.02mm precision, meeting the most stringent tolerances for critical applications.

Advanced Machining Capabilities for Complex Titanium Components

Equipped with state-of-the-art 5-axis CNC machines and decades of expertise, we specialize in producing:

1. Precision-CNC titanium machining

- B Wing brackets, engine mounts, and landing gear components requiring high fatigue resistance and minimal weight.

- Medical Implants: Biocompatible titanium orthopedic implants (hip stems, bone plates) and dental fixtures, polished to Ra 0.2μm for smooth, tissue-friendly surfaces.

- Industrial Components: High-speed turbine shafts, corrosion-resistant valves, and robotic arm links for automation systems.

2. Complex Geometry Mastery

- 5-Axis Simultaneous Machining: Effortlessly creates intricate contours, deep cavities, and multi-angle features (e.g., aerofoil shapes, internal cooling channels).

- Swiss-Type CNC Lathes: Specialized for micro-titanium parts as small as 2mm, ideal for connectors, fasteners, and miniature mechanical components.

- Grinding & Honing: Achieve mirror-like surface finishes and tight dimensional tolerances for parts requiring low friction or optical precision.

3. Customization at Every Stage

- Material Selection: Choose from grade 2 (commercially pure), grade 5 (Ti-6Al-4V), or exotic alloys like Ti-10V-2Fe-3Al for specific strength, ductility, or heat resistance needs.

- Anodizing: Enhance corrosion resistance and aesthetic appeal with colored coatings.

- PVD (Physical Vapor Deposition): Apply wear-resistant coatings (e.g., TiN, TiCN) to extend part life in high-load applications.

- Electropolishing: Achieve smooth, bacteria-resistant surfaces for medical devices.

Why Choose Ganyuan for CNC Titanium Machining?

1. Technical Excellence & Advanced Facilities

- 2,000m² Factory: Equipped with 5-axis CNC machining centers, CNC lathes, and EDM wire-cutting machines, capable of handling titanium parts up to 2,000mm in length.

- 20+ Years of Expertise: Deep understanding of titanium’s unique machining characteristics (low thermal conductivity, high elasticity) to optimize cutting parameters and prevent tool wear.

2. Rigorous Quality Assurance

- ISO 9001:2015 Certified: Every titanium part undergoes:

- First Article Inspection (FAI): Comprehensive dimensional and material testing using 3D CMM (Coordinate Measuring Machine).

- Material Traceability: Mill test reports and heat lot certification for full compliance with industry standards.

- In-Process QC: Real-time monitoring of spindle speed, feed rate, and tool wear to ensure consistency in large production runs.

3. Flexible & Efficient Service

- Low MOQ: Start with as few as 5 pieces for prototyping, scaling to 10,000+ units for mass production.

- Fast Turnaround: 7–15 days for proofing and 15–25 days for production orders, including surface treatment and packaging.

- Global Logistics: FOB Dongguan shipping with customized packaging (anti-static bags, wooden crates) to protect parts during transit.

4. Engineering Support from Concept to Completion

- Design Optimization: Our team provides DFM (Design for Manufacturing) feedback to refine your titanium part designs, balancing performance with cost efficiency.

- Rapid Prototyping: Convert STEP/IGES/PDF files into functional titanium prototypes using CNC machining, ensuring design validation before full production.

Advanced Manufacturing Capabilities

With over 20 years of expertise in CNC machining, we utilize state-of-the-art technology to produce CNC titanium machining with tight tolerances and flawless finishes. Our facility in Dongguan, China, spans 2,000 square meters and is equipped with:

-

5-Axis & 4-Axis CNC Machines – For complex geometries and high-precision machining.

-

CNC Lathes & Milling Machines – Ensuring dimensional accuracy and smooth surface finishes.

-

Stamping & Die-Casting Equipment – For custom CNC titanium machining designs.Stainless steel shaft

Material Excellence & Customization

We collaborate with top-tier material suppliers to guarantee the highest quality CNC titanium machining. Available materials include:

-

Stainless Steel (303, 304, 316) – For superior corrosion resistance.

-

Aluminum Alloy (6061, 6063, 7075) – Lightweight yet durable.

-

Carbon Steel (1045, 1215) – High strength for industrial use.

-

Titanium, Brass, Bronze, and Engineering Plastics – For specialized applications.

Reliable Packaging & Global Shipping

We ensure safe delivery of CNC titanium machining with customized packaging:

-

Commercial Packaging – Individual plastic bags + cartons + pallets.

-

Industrial Packaging – Protective tubes + kraft paper + wooden crates.

-

Customer-Specified Packaging – Tailored to your logistics needs.

Partner with Us for Premium CNC titanium machining

At Dongguan Ganyuan Hardware Technology Co., Ltd., we combine advanced manufacturing, rigorous quality control, and innovative R&D to produce CNC titanium machining that exceed industry standards. Whether you need standard or custom-engineered solutions, our team is ready to meet your requirements.

Competitive Advantages

✅ 20+ Years of ratchet mechanism expertise

✅ ISO 9001:2015 certified production

✅ Prototype to 10,000+ unit production runs

✅ DFM support to optimize tooth geometry

Request a Free Design Consultation

📧 Email: ganyuan1688@gmail.com

📱 WhatsApp: +86 139 2925 6361

🌐 Online Quote: https://www.ganyuan.net/

Dongguan Ganyuan Hardware Technology Co., Ltd.

📍 Factory Address: 1st Floor, Building A, No. 78, Yintong Road, Shuikou Industrial Zone, Dalang Town, Dongguan City, Guangdong Province, China

🏭 Facility: 2,000m² | 5-Axis CNC Machining Center