We are seeking suppliers for five-axis CNC machining plant machinery parts. Our company, Dongguan Ganyuan Hardware Technology Co., Ltd., specializes in manufacturing and supplying customized machine parts. With our precision machining services, we provide a wide range of industrial machine parts, including aluminum and steel components. Our expertise extends to automotive, aerospace, and electronic components, as well as plastic injection molding services. We offer contract manufacturing services and integrated solutions for all your industrial equipment part needs. Contact us for high-quality metal components.

| Production type |

Customized production and processing |

Material |

Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

| Processing method |

cnc lathe machine parts 5-axis CNC machining center, grinder, wire cutting |

Processing equipment |

cnc lathe machine parts Five-axis CNC machining center, grinder, wire cutting |

| accuracy |

±0.02mm |

Whether to proof |

Yes |

| Whether to customize |

Yes |

Proofing time |

7-15 days |

| OEM/ODM |

OEM ODM CNC machining services |

surface treatment |

Electroplating, zinc plating, chromium plating, nickel plating, oxidation, hard oxidation |

| origin |

Dongguan, China |

Quotes |

fob price |

| Business type: |

Manufacturers/factories and trading companies |

Main products: |

CNC parts; machined parts;cnc lathe machine parts |

| Management system certification: |

ISO 9001:2015 |

Average delivery time: |

Peak season delivery time: within 15 working days Low season delivery time: within 15 working days |

1. What are the advantages of ganyuan‘s customized stainless steel processing spare parts?

Highly efficient production

The use of advanced machining equipment and technology ensures an efficient production process and shortens lead times.

Consistency

: Ensure consistent size and shape of each part through strict quality control to minimize human error.

Cost Control

Despite the high initial investment in equipment, the cost advantage in the long run is achieved by reducing material waste and labor costs.

Customization

We provide personalized design and processing services according to the specific needs of our customers to meet the requirements of different application scenarios.

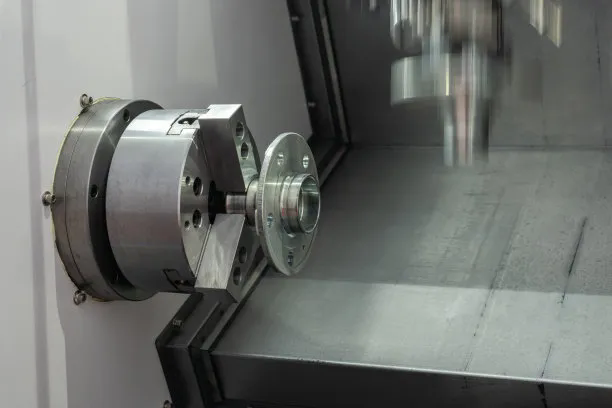

CNC lathe machine parts: Precision crafted for reliable performance, ensuring accuracy and durability.

2. What technologies does ganyuan use to ensure the high precision of its parts?

We use advanced numerical control (CNC) machining technology that enables us to achieve micron-level machining accuracy. Our equipment includes high-precision CNC lathes, milling machines, and grinders to ensure that the size and shape of each part meets design requirements.

3. How does ganyuan treat the surface of stainless steel parts?

We offer a variety of surface treatment options, including sandblasting, plating, polishing and anodizing. These treatments not only improve the corrosion resistance and aesthetics of the part, but also enhance its mechanical properties.

4. How do ganyuan‘s stainless steel machining spares perform in terms of durability?

Our stainless steel machining spares undergo rigorous testing and quality control to ensure high performance and long life in a variety of environments. Whether it is high temperature, high pressure or corrosive environments, our parts are built to last.

5. What are the applications for ganyuan‘s stainless steel machined spare parts?

These parts are widely used in demanding industrial applications such as aerospace, automotive manufacturing, medical equipment, and precision instruments. Their high precision and reliability make them indispensable key components in these fields.

We are a manufacturer integrating industry and trade. We have more than 20 years of experience in production technology. We are located in Dongguan City, Guangdong Province, China. We have advanced high-end professional production and processing technology and are committed to innovative R&D and production. After years of market training and exploration, we have high-quality technical management talents, experienced designers, R&D personnel and a complete company management system.

cnc lathe machine parts

Our factory has a building area of about 2,000 square meters and masters core processing technology. It has high-end precision production equipment: cnc lathe machine parts, 5-axis CNC, 4-axis CNC, stamping equipment, die-casting equipment, etc.

Auxiliary production equipment: electroplating, anodizing, hard anodizing, surface treatment. We have complete testing equipment: sophisticated three-dimensional testing, two-dimensional testing, hardness testers, altimeters, projectors and other conventional testing equipment. If you are interested in our products,

please contact me and I will provide the best price support and quality service.

Our advantages

We cooperate with many high-quality material suppliers, and the quality is very guaranteed. Please feel free to choose our materials. At the same time, supporting documents can be provided for all materials. Materials include aluminum alloy, steel alloy, carbon steel, stainless steel, copper, brass, titanium alloy, bronze, nylon, acrylic, etc. Aluminum 6061/6063/7075; Iron 1215/45/1045; Stainless steel 303/304/316; Copper; Brass; Bronze (H59/H62/T2/H65); Plastic POM/PE/PSU/PA/PEEK, etc. can be based on Customers require production.

surface treatment

For surface treatment, our suppliers have been working with us for many years. They have extensive experience and are familiar with all each other’s quality requirements. Stable quality is more guaranteed. Such as: heat treatment, spray painting, powder coating, blackening, silver/gold plating, electrolytic polishing, nitriding, phosphating, nickel/zinc/chromium/TiCN plating, anodizing, polishing, passivation, sandblasting, galvanizing, Heat treatment, hardening, laser marking, etc. can be performed according to customer requirements.

FAQ

Q1: Where can I get product and price information? A1: Send us an inquiry email, we will contact you after receiving your email.

Q2: How long does it take for me to get the sample? A2: Depends on your specific project, usually within 3-7 days.

Q3: What types of information are required for quotations? A3: Please provide product drawings in PDF form, it would be better if provided in STEP or IGS form.

Q4: What are the payment terms? A4: We accept 50% as payment deposit, when the goods are ready, we take photos or videos for your inspection, then you can pay the balance. For small quantities, we accept Paypal and commission will be added to the order. For large amounts, T/T is preferred.

Q5: How to deliver the goods? A5: We ship products via express company.

Q6: Are you a trading company or a factory? A6: We are factory direct sales, with 17 experienced engineers and more than 50 employees, and a workshop area of about 3,000 square meters.

Q7: What should I do if I don’t have drawings? A7: Please send your samples to our factory, then we can copy and provide you with better solutions. If you send us a picture or draft with dimensions (length, height, width), we will make a CAD or 3D file for you.

Q8: Can we get some samples before mass production? A8: Absolutely.

Q9: Are my drawings safe after being sent to you? A9: Yes, we will keep them properly and will not release them to third parties without your permission.

Q10: Can I understand the running status of my product without going to your company? A10: We will provide detailed production plans and send weekly reports with digital pictures and videos showing the processing progress.

Q11: If the quality of the goods you produce is not good, will you refund? A11: In fact, we will not take the risk of producing inferior products. At the same time, we manufacture quality products until you are satisfied.

Packaging details 1. Commercial packaging: 1 piece/plastic bag + color box + carton + pallet; 2. Industrial packaging: (1). Plastic tube + carton + pallet; (2). Plastic bag + kraft paper + carton + pallet; 3. According to customer requirements.