Product Categories

- Brass Parts (10)

- Plastic Parts (12)

- Aluminum alloy products/accessories (83)

- Precision Machinery Parts (172)

- Watch/Jewelry Accessories (5)

- Stainless Steel Products/Accessories (132)

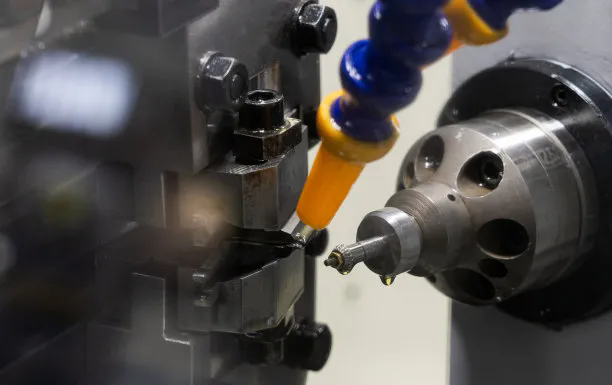

- cnc turning parts (121)

Premium car auto parts here! Engineered for excellence, they guarantee reliable operation, noise reduction, and extended service life.

Dive into high – quality stainless steel production.Our experienced team creates stainless steel products with outstanding strength and aesthetic appeal.

Motor shaft copper sleeve: The material is H59 brass which is precision CNC turned, then 5-axis CNC milled, and finally electroplated for surface treatment.

![]()

Robot accessory bracket: Made of AL6061 aluminum alloy after 5-axis milling and then oxidized natural surface treatment.

Fine-tuning dial: It is used for scale adjustment of terminal machines and mechanical equipment. It is made of high-hardness and durable carbon steel, processed by CNC lathe and precision 5-axis CNC, and then electroplated on the surface.

Fine-tuning dial: It is used for scale adjustment of terminal machines and mechanical equipment. It is made of high-hardness and durable carbon steel, processed by CNC lathe and precision 5-axis CNC, and then electroplated on the surface.

Speech microphone: AL6063 aluminum alloy material is processed by CNC lathe and 5-axis CNC, and then oxidized gold on the surface. It is used in: KTV, schools, karaoke halls, stages, speeches and other public places.

![]()

Titanium alloy interface: Made of Tc4 titanium alloy material through precision CNC processing and 5-axis CNC processing. It is used in: equipment interfaces, mechanical interfaces, aviation plug interfaces, etc.

![]()

We are a manufacturer integrating industry and trade. We have more than 20 years of experience in production technology. We are located in Dongguan City, Guangdong Province, China. We have advanced high-end professional production and processing technology, and are committed to innovative R&D and production. After years of market tempering and exploration, it has high-quality technical management personnel, experienced designers, R&D personnel and a perfect company management system car auto parts.

Our factory has a plant area of about 2,000 square meters and masters core processing technologies. It has high-end precision production equipment: CNC lathes, 5-axis CNC, 4-axis CNC, stamping equipment, die-casting equipment, etc.

Auxiliary production equipment: electroplating, anodizing, hard anodizing and surface treatment.

We have complete testing equipment: sophisticated three-dimensional testing, two-dimensional testing, hardness tester, height meter, projector and other conventional testing equipment.

If you are interested in our products, please contact me and I will provide the best price support and quality service car auto parts.

I believe we will establish a good and long-term cooperation.

Welcome to send pictures and letters to discuss, thank you!

We cooperate with many high-quality material suppliers, and the quality is very guaranteed. Please feel free to choose our materials. At the same time, supporting documents can be provided for all materials. Materials are available, such as aluminum alloy, steel alloy, carbon steel, stainless steel, copper, brass, titanium alloy, bronze, nylon, acrylic, cnc machined components,etc.

Aluminum 6061/6063/7075; Iron 1215/45/1045; Stainless steel 303/304/316; Copper; Brass; Bronze (H59/H62/T2/H65); Plastic POM/PE/PSU/PA/PEEK, etc. can be based on Customer requirements.

For surface treatment, our suppliers have been working with us for many years. They have rich experience and are familiar with all the quality requirements of each other. The quality is stable and more guaranteed. Such as: heat treatment, spray painting, powder coating, blackening, silver/gold plating, electrolytic polishing, nitriding, phosphating, nickel/zinc/chromium/TiCN plating, anodizing, polishing, passivation, sandblasting, galvanizing, heat treatment , hardening, laser marking, etc. according to customer requirements.