Product Categories

- Brass Parts (10)

- Plastic Parts (12)

- Aluminum alloy products/accessories (83)

- Precision Machinery Parts (172)

- Watch/Jewelry Accessories (5)

- Stainless Steel Products/Accessories (132)

- cnc turning parts (121)

When it comes to Brass Precision Parts, quality and precision are non-negotiable. Whether you need components for automotive, plumbing, electronics, or industrial machinery, our brass parts are manufactured from premium-grade brass to ensure durability, corrosion resistance, and exceptional performance.

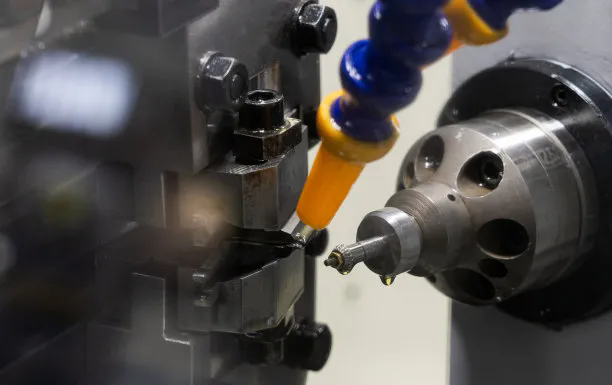

| Production type | Custom production and processing | Material | Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting,cnc machined components |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | Dongguan, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts; Machining parts;brass precision parts |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

Brass is a preferred material for precision machining due to its unique properties:

Trusted supplier of precision brass machined parts, combining craftsmanship with advanced manufacturing for flawless functionality.

Brass offers a perfect balance of strength and hardness, making it ideal for high-load applications. Our CNC-machined brass parts maintain structural integrity under stress, resisting deformation and wear over time.brass precision parts

Brass naturally resists oxidation and chemical reactions, ensuring long-term stability even when exposed to fuels, coolants, and lubricants. This makes brass precision parts highly reliable in automotive and marine environments.brass precision parts

Brass is easy to machine, allowing for tight tolerances (±0.02 mm) and intricate designs. Our advanced CNC lathes and multi-axis milling machines produce flawless brass precision parts that meet the most demanding specifications.

With over 20 years of experience in precision machining, we combine cutting-edge technology with meticulous craftsmanship to deliver top-tier brass components.brass precision parts

2,000m² production area with 5-axis CNC centers

Acoustic engineering support for customized solutions

Complete quality control including frequency response testing

We work with a wide range of brass alloys (H59, H62, H65, T2) and offer:

Prototyping & mass production

Custom designs based on drawings or samples

Multiple surface finishes (polishing, plating, sandblasting, laser marking, etc.)

✅ Low MOQ (10 pieces) – Ideal for prototypes and small-batch production.

✅ Fast lead time (15 days) – Quick turnaround without sacrificing quality.

✅ Competitive pricing – Cost-effective solutions for bulk orders.

✅ Material variety – Brass, bronze, copper, aluminum, stainless steel, and more.

✅ Full documentation – Material certifications, inspection reports, and compliance records.

We offer flexible packaging options:

Commercial packaging (plastic bags + cartons + pallets)

Industrial packaging (plastic tubes + kraft paper + wooden crates)

Custom packaging per customer requirements