Product Categories

- Brass Parts (11)

- Plastic Parts (16)

- Aluminum alloy products/accessories (92)

- Precision Machinery Parts (187)

- Watch/Jewelry Accessories (6)

- Stainless Steel Products/Accessories (151)

- cnc turning parts (121)

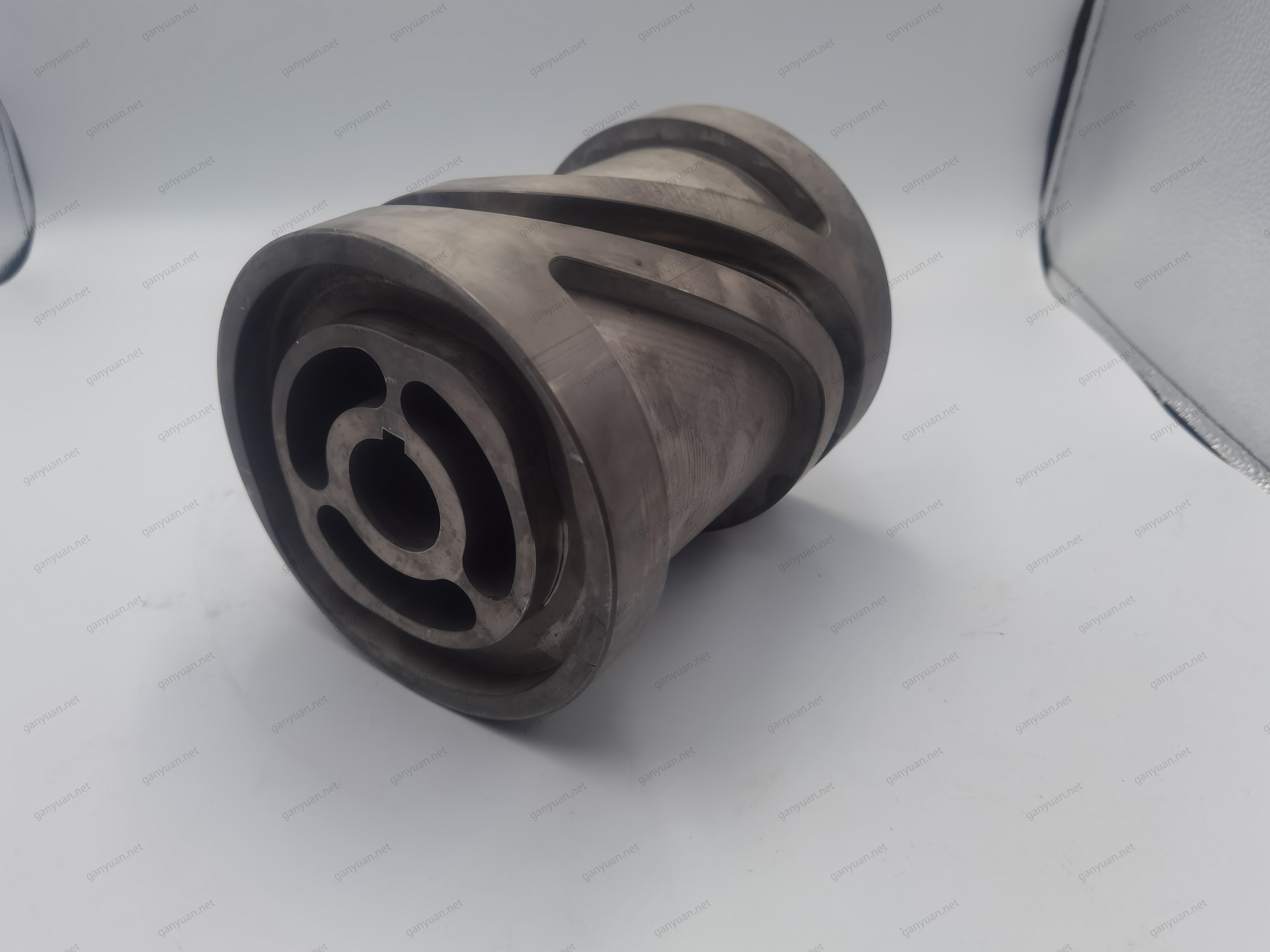

In the competitive world of automotive manufacturing, precision and reliability are non-negotiable. Our auto CNC machining services stand out as a leader in the industry, delivering unmatched accuracy, efficiency, and durability for all types of automotive components. Equipped with state-of-the-art 5-axis CNC machines, 4-axis CNC milling, and advanced turning centers, we ensure every part meets the strictest tolerance standards—down to ±0.02mm—for flawless performance in critical automotive applications.

| Production type | Custom production and processing | Material | Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting,Cnc Auto Part |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | Dongguan, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts; Machining parts;auto cnc machining |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

From engine blocks and transmission gears to suspension components and brake system parts, our auto cnc machining expertise covers a wide range of materials, including:

Aluminum alloys (6061, 7075)

Stainless steel (303, 304, 316)

Carbon steel & alloy steel

Titanium, brass, and engineered plastics (PEEK, Nylon, POM)

With a minimum order quantity of just 10 pieces and a fast turnaround time of 15 days, we provide scalable solutions for both prototyping and mass production.

Dive into the world of efficient manufacturing with our auto CNC machining. Automated excellence ensures quick turnarounds and flawless parts.

Our auto CNC machining processes utilize high-speed CNC milling and multi-axis turning to produce complex geometries with ultra-tight tolerances. Whether you need high-strength crankshafts, precision gear sets, or custom chassis components, our machines deliver superior surface finishes and dimensional accuracy.

We partner with top-tier material suppliers to ensure durability and performance. Additionally, our auto CNC machining can undergo various surface treatments, including:

Anodizing (Type II & Type III)

Powder coating & electroplating

Heat treatment (quenching, tempering, case hardening)

Laser engraving & sandblasting

Every component undergoes strict inspection using:

3D CMM (Coordinate Measuring Machines)

Hardness testers & optical comparators

Surface roughness testers

This ensures compliance with ISO 9001 and IATF 16949 automotive standards.

Our expertise extends across multiple automotive sectors:

✔ Powertrain Systems (Engine blocks, pistons, camshafts)

✔ Transmission & Drivetrain (Gears, shafts, differential housings)

✔ Suspension & Steering (Control arms, knuckles, ball joints)

✔ Braking Systems (Calipers, rotors, master cylinders)

✔ Custom Performance & Racing Components

Located in Dongguan, China, our 2,000 sqm facility is equipped with:

5-axis & 4-axis CNC machining centers

Swiss-type CNC lathes

Precision grinding & EDM machines

Stamping & die-casting units

Our team of 20+ years of experienced engineers ensures every project meets the highest industry benchmarks.

✅ Tolerances as tight as ±0.02mm

✅ Fast prototyping & low MOQ (10 pieces)

✅ One-stop machining & finishing services

✅ Strict quality assurance with full traceability

✅ Competitive pricing & on-time delivery