Product Categories

- Brass Parts (11)

- Plastic Parts (20)

- Aluminum alloy products/accessories (104)

- Precision Machinery Parts (205)

- Watch/Jewelry Accessories (6)

- Stainless Steel Products/Accessories (171)

- cnc turning parts (123)

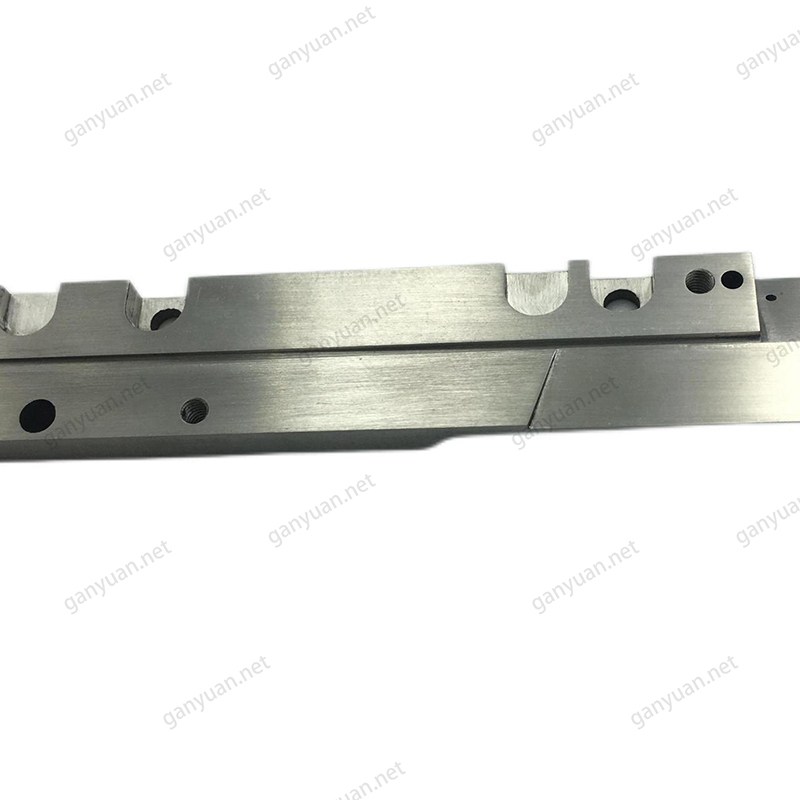

Manufactured with advanced cnc milling machining technology, these rails maintain strict tolerances of ±0.02 mm, making them ideal for aerospace, medical equipment, chemical processing, and food machinery industries. The meticulous engineering behind CNC rails guarantees reliability in even the most demanding operational conditions.

Product Description

| Production type | Custom production and processing | Material | Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting,cnc machined components |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | Dongguan, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts; Machining parts;cnc milling machining |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

CNC rails represent the gold standard in linear motion systems, offering unparalleled accuracy and smooth operation for industrial applications. Our precision cnc milling machining rails feature a superior surface finish that ensures consistent performance in high-speed environments where exact positioning and frictionless movement are critical.cnc rails

Our CNC rails utilize high-grade stainless steel, known for its excellent machinability and durability. While stainless steel presents some machining challenges compared to softer materials, our expertise in tool selection (including carbide cutters) and optimized cutting parameters ensures flawless results. Combined with specialized cooling and lubrication techniques, we achieve complex geometries and ultra-precise dimensions.

With over 20 years of experience in precision manufacturing, our facility in Dongguan, Guangdong, China, spans 2,000 square meters and houses state-of-the-art equipment, including:

CNC lathes for high-tolerance turning

5-axis & 4-axis cnc milling machining for intricate multi-directional machining

Stamping and die-casting equipment for high-volume production

Surface treatment options such as electroplating, anodizing, and hard coating

We employ advanced inspection tools to guarantee the highest standards:

3D & 2D measuring systems for dimensional accuracy

Hardness testers for material integrity verification

Projectors and height gauges for detailed component analysis

CNC rails serve as critical components in industries requiring precision linear motion, including:

Aerospace: Guidance systems and actuator mechanisms

Medical Devices: Robotic surgery equipment and imaging systems

Industrial Automation: High-speed CNC machines and robotic arms

Food & Chemical Processing: Corrosion-resistant conveying systems

We collaborate closely with clients to develop tailored solutions based on precise drawings or samples. Our material options include:

Metals: Aluminum 6061/7075, Stainless Steel 303/316, Titanium, Brass, Bronze

Plastics: POM, PEEK, Nylon for lightweight or non-conductive applications

To enhance durability and performance, we offer:

Anodizing & Hard Coatings for wear resistance

Electroless Nickel Plating for corrosion protection

Polishing & Sandblasting for superior finishes

Heat Treatment for increased hardness

✅ Tolerances as tight as ±0.02mm

✅ Fast prototyping & low MOQ (10 pieces)

✅ One-stop machining & finishing services

✅ Strict quality assurance with full traceability

✅ Competitive pricing & on-time delivery

“Your design vision, our engineering precision – let’s create something extraordinary.”

Request a Free Project Review

📧 Email: ganyuan1688@gmail.com

🌐 Website: https://www.ganyuan.net/

📞 Tel: 86–13929256361

Dongguan Ganyuan Hardware Technology Co., Ltd.