Product Categories

- Brass Parts (11)

- Plastic Parts (17)

- Aluminum alloy products/accessories (100)

- Precision Machinery Parts (195)

- Watch/Jewelry Accessories (6)

- Stainless Steel Products/Accessories (160)

- cnc turning parts (121)

CNC aluminum parts are revolutionizing modern manufacturing with their exceptional precision, lightweight properties, and high durability. Ideal for industries ranging from aerospace to automotive, these components are engineered to meet the most demanding performance standards. At Dongguan Ganyuan Hardware Technology Co., Ltd., we specialize in producing top-tier CNC aluminum parts using advanced five-axis and four-axis machining techniques, ensuring unmatched accuracy and efficiency.

| Production type | Custom production and processing | Material | Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC machining center, grinder, cnc aluminum parts |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | Dongguan, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts; Machining parts;cnc aluminum parts |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

Precision Engineering – Our CNC aluminum parts are manufactured using high-precision CNC lathes and five-axis milling machines, guaranteeing tight tolerances and flawless finishes.

Lightweight & Strong – Aluminum alloys like 6061, 6063, and 7075 provide an optimal strength-to-weight ratio, making them perfect for high-performance applications.

Versatility – From complex curved surfaces to intricate geometries, our CNC machining capabilities allow for diverse and delicate designs.

Corrosion Resistance – With advanced surface treatments like anodizing and plating, our CNC aluminum parts offer enhanced durability and longevity.

![]()

Our CNC lathes ensure precise dimensional accuracy for cylindrical and rotational parts, making them ideal for shafts, connectors, and housings.

For intricate 3D contours and complex shapes, our five-axis CNC milling machines deliver superior surface finishes and exacting precision.

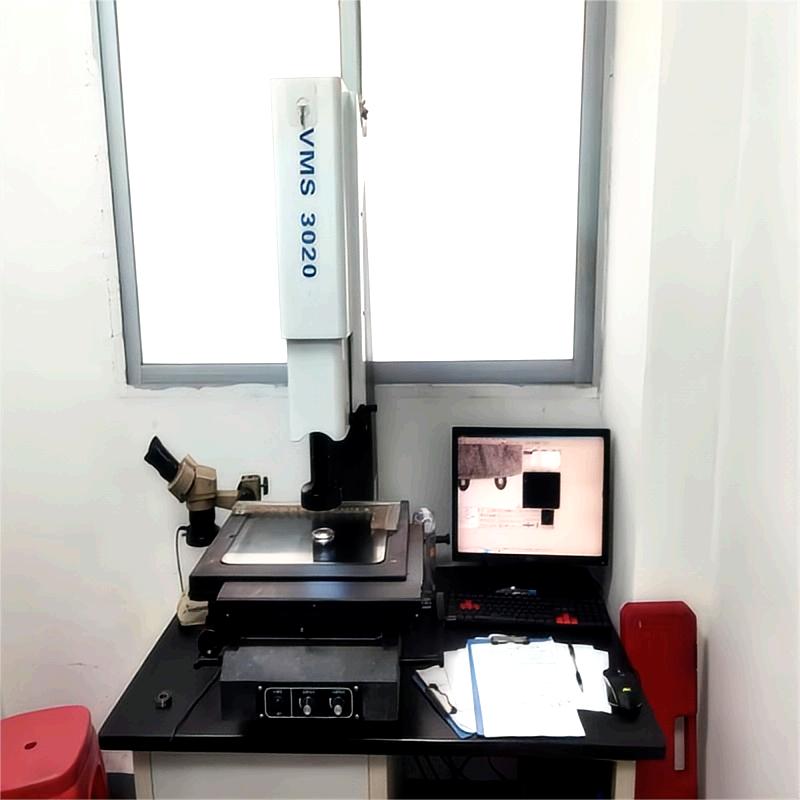

We employ advanced inspection equipment, including 2.5D and 3D measuring systems, to guarantee every CNC aluminum part meets rigorous quality standards.

Aerospace – Lightweight yet strong components for aircraft and satellites.

Automotive – High-performance parts for engines, transmissions, and structural components.

Precision Instruments – Medical devices, robotics, and optical equipment requiring ultra-fine tolerances.

Consumer Electronics – Durable and aesthetically pleasing enclosures and heat sinks.

2,000+ sqm production workshop

High-end CNC lathes, 4-axis & 5-axis CNC machines

Advanced surface treatment options (anodizing, plating, powder coating, etc.)

Aluminum Alloys: 6061, 6063, 7075

Stainless Steel: 303, 304, 316

Copper, Brass, Titanium, Plastics (POM, PEEK, etc.)

We offer tailored solutions with:

Anodizing (color, hard coat)

Electroplating (gold, silver, nickel, chrome)

Powder Coating & Sandblasting

Laser Marking & Heat Treatment

✔ 20+ Years of Expertise in CNC machining

✔ High-Quality Materials & Strict QC

✔ Competitive Pricing & Fast Lead Times

✔ One-Stop Custom Manufacturing Solutions

To ensure safe delivery, we provide:

Commercial Packaging (plastic bags + cartons + pallets)

Industrial Packaging (plastic tubes + kraft paper + wooden crates)

Custom Packaging based on client requirements

Request Your Custom Quote Today!

📧 Email: ganyuan1688@gmail.com

🌐 Website: ganyuan1688@gmail.com

📞 Tel: 86–13929256361

Why Choose Us?

→ Precision CNC Milling Parts (±0.02mm)

→ Fast Turnaround (10-15 Days)

→ Medical, Automotive & Aerospace Expertise

→ Competitive Pricing & Quality Guarantee

Upgrade Your Manufacturing with Our Precision Components! 🚀