Product Categories

- Brass Parts (11)

- Plastic Parts (17)

- Aluminum alloy products/accessories (100)

- Precision Machinery Parts (195)

- Watch/Jewelry Accessories (6)

- Stainless Steel Products/Accessories (160)

- cnc turning parts (121)

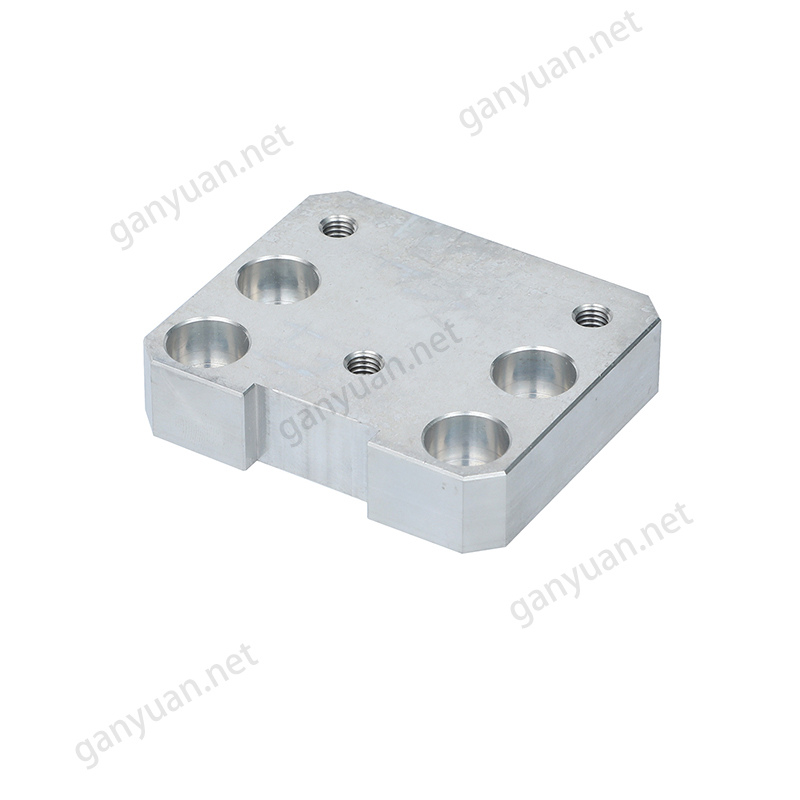

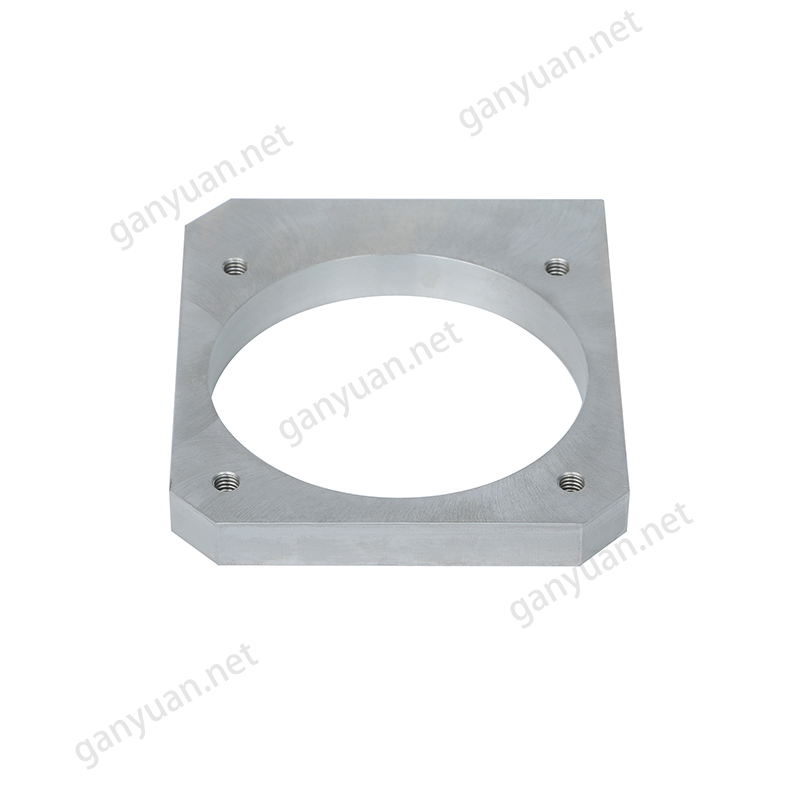

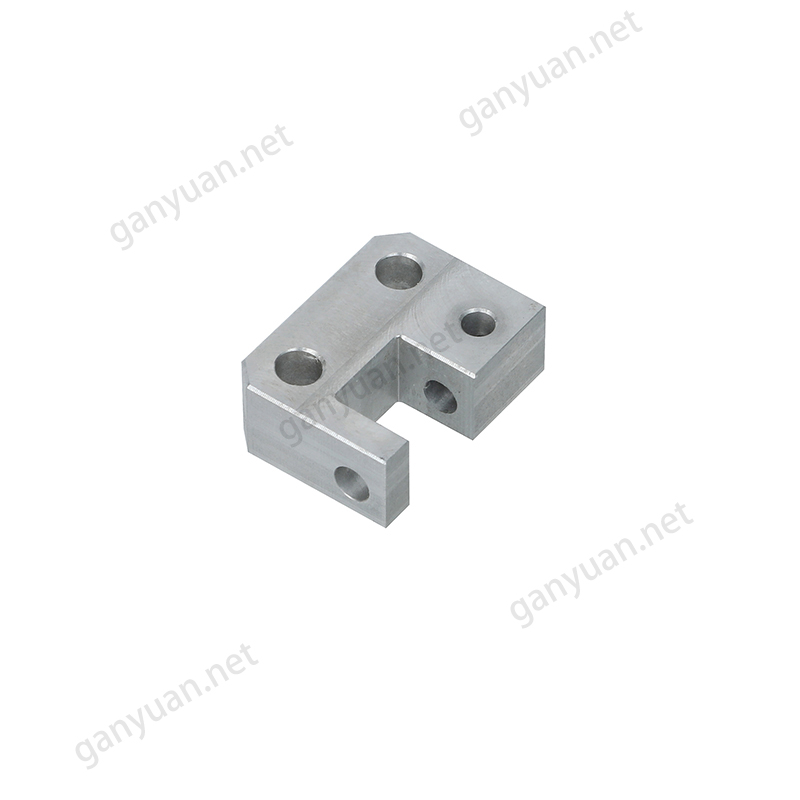

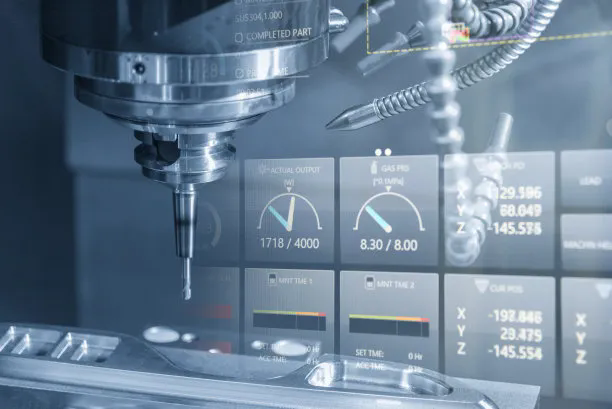

High-quality aluminum CNC machining parts are essential for industries that demand precision, durability, and superior performance. These parts are manufactured using advanced CNC (Computer Numerical Control) technology, ensuring tight tolerances, excellent surface finishes, and long-lasting reliability. Whether for aerospace, automotive, medical, or industrial applications, aluminum CNC machining parts provide the strength and lightweight properties needed for high-performance machinery.

| Production type | Custom production and processing | Material | Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | Dongguan, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | cnc parts; Machining parts,aluminum cnc machining part |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

At Dongguan Ganyuan Hardware Technology Co., Ltd., we specialize in producing top-tier CNC machining parts, including five-axis and four-axis CNC components, designed to optimize efficiency and precision in modern manufacturing.

CNC aluminum cnc machining part with strict tolerances and smooth finishes. Perfect for high-performance applications in various industries.

Aluminum is one of the most popular materials for CNC machining due to its unique advantages:

Lightweight yet Strong: Aluminum alloys, such as 7075-T651, offer exceptional strength-to-weight ratios, making them ideal for high-stress applications.

Excellent Machinability: Aluminum is easier to machine than steel or titanium, reducing production time and costs.

Superior Corrosion Resistance: With proper surface treatments (e.g., anodizing), aluminum CNC machining parts can withstand harsh environments.

Thermal & Electrical Conductivity: Aluminum efficiently dissipates heat, making it suitable for electronic and automotive components.

We utilize cutting-edge five-axis and four-axis CNC machining to produce complex geometries with unmatched accuracy. Our capabilities include:

High-Speed Precision Milling: Ensures smooth finishes and tight tolerances (±0.005mm).

Multi-Axis Machining: Allows for intricate designs without multiple setups.

Custom Surface Finishing: Options include anodizing, powder coating, electroplating, and more.

Our aluminum CNC machining parts are trusted in various high-demand sectors:

Aerospace: Lightweight, high-strength components for aircraft and satellites.

Automotive: Engine parts, brackets, and structural components.

Medical: Surgical instruments and implantable devices with biocompatible finishes.

Industrial Machinery: Durable, wear-resistant parts for heavy-duty applications.

We work with premium-grade materials, including:

Aluminum Alloys: 6061, 6063, 7075

Stainless Steel: 303, 304, 316

Copper, Brass, Titanium, and Engineering Plastics

Available surface treatments enhance durability and aesthetics:

Anodizing (Clear/Black/Color)

Powder Coating & Spray Painting

Electroplating (Nickel, Zinc, Chrome, Gold, etc.)

Sandblasting & Polishing

20+ Years of Expertise: We combine traditional craftsmanship with modern CNC technology.

Strict Quality Control: Advanced 2.5D/3D inspection ensures flawless parts.

Custom Solutions: Tailored machining services to meet unique specifications.

Fast Turnaround & Competitive Pricing: Efficient production without compromising quality.

“Your design vision, our engineering precision – let’s create something extraordinary.”

Request a Free Project Review

📧 Email: ganyuan1688@gmail.com

🌐 Website: ganyuan1688@gmail.com

📞 Tel: 86–13929256361

Dongguan Ganyuan Hardware Technology Co., Ltd.