At Dongguan Ganyuan Hardware Technology Co., Ltd., we specialize in manufacturing high – performance Flashlight Housing that meets the most demanding requirements of flashlight manufacturers. Our

Flashlight Housing is crafted with the same level of precision, durability, and consistency as our renowned PCB material wheels, making it a top – choice in the industry.

- Production type: We offer custom production and processing services. Whether you need a small batch for prototyping or a large – scale production run, our team is equipped to handle your needs.

- Material: We work with a variety of materials, including metal, non – metal, carbon steel, stainless steel, copper, and aluminum alloy. For Flashlight Housing, aluminum alloy, especially aerospace – grade 6061 – T6/7075 – T6, is a popular choice due to its lightweight yet rigid properties, ensuring the flashlight is easy to carry while maintaining structural integrity.

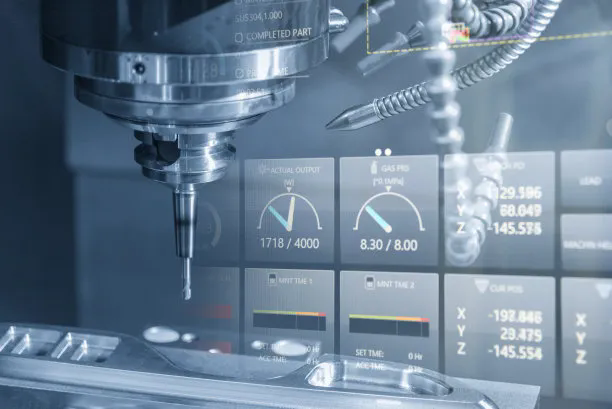

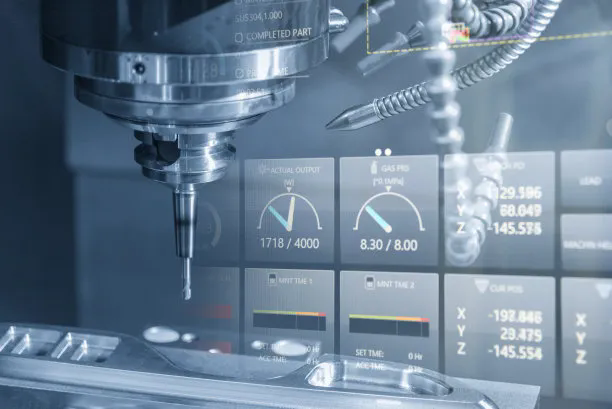

- Processing methods: Our advanced 5 – axis CNC machining centers, grinding machines, and wire – cutting equipment are used to shape the Flashlight Housing with utmost precision. The 5 – axis CNC machining allows for complex geometries to be created, ensuring a perfect fit for all internal components of the flashlight.

- Processing Equipment: We have state – of – the – art CNC Trining Parts 5 – axis CNC machining centers, grinders, wire cutting, and Cnc Auto Part equipment. These machines are regularly maintained to ensure consistent accuracy.

- Accuracy: We achieve an impressive accuracy of ±0.02mm, guaranteeing that each Flashlight Housing is made to the exact specifications. This high level of precision ensures proper assembly and functionality of the flashlight.

- Whether proofing: Yes, we offer proofing services. We understand the importance of getting the design right before mass production, and our proofing process is efficient and detailed.

- Is it customized: Absolutely. We can customize the Flashlight Housing according to your specific design requirements, including shape, size, and any additional features.

- Proofing time: Generally, the proofing time is 7 – 15 days, depending on the complexity of the design.

- OEM/ODM: We provide OEM ODM CNC machining services. Our experienced engineers can work with you from the initial design concept to the final product, taking care of all aspects of manufacturing.

- Surface treatment: We offer a range of surface treatments, such as electroplating, zinc plating, chrome plating, nickel plating, oxidation, and hard oxidation. These treatments not only enhance the aesthetic appeal of the Flashlight Housing but also improve its corrosion resistance and durability.

- Origin: Our products are made in Dongguan, China, where our 2,000 sqm facility is equipped with advanced manufacturing equipment.

- Quotations: We offer FOB quotations, providing you with transparent and competitive pricing.

- Premium Alloy Selection: Just like our PCB material wheels, we use high – quality materials. The aerospace – grade aluminum alloy used in our Flashlight Housing offers excellent heat dissipation properties, which is crucial for flashlights that generate heat during operation. This helps to extend the lifespan of the flashlight’s LED components.

- Specialty Coatings: We apply coatings such as TiN/TiAlN to the Flashlight Housing. These coatings reduce friction, making it easier to grip the flashlight, and also help in heat buildup prevention, ensuring a comfortable and safe user experience.

- 5 – axis CNC Machined: Our Flashlight Housing is 5 – axis CNC machined to achieve perfect balance. The tight tolerance of ±0.005mm TIR (Total Indicator Runout) ensures that the housing is free from any wobbling or misalignment, which could affect the flashlight’s performance.

- Custom Geometries: We can create custom geometries for the Flashlight Housing to fit unique flashlight designs. Whether it’s a specific shape for better ergonomics or a design to accommodate new types of batteries or LED modules, our team can make it happen.

- Anti – vibration Features: The Flashlight Housing is designed with anti – vibration slots. These slots reduce vibrations during operation, ensuring a stable light beam. This is especially important for flashlights used in outdoor activities or in situations where a steady light source is crucial.

- Heat – dissipation Design: In addition to the material’s natural heat – dissipation properties, our Flashlight Housing is designed with channels and fins to further enhance heat dissipation. This helps to keep the flashlight cool during long – term use, preventing overheating and potential damage to the internal components.

- Different Sizes and Shapes: We can manufacture Flashlight Housing in various sizes and shapes to fit different types of flashlights, from small keychain flashlights to large, high – powered tactical flashlights.

- Mounting Options: Our Flashlight Housing can be designed with different mounting options, such as clips for easy attachment to belts or bags, or threaded mounts for tripod or other accessory attachments.

- Diameter Range: We can produce Flashlight Housing with a diameter range that can be customized according to your needs. For standard designs, we can offer a wide range to fit common flashlight sizes.

- Length and Width Options: The length and width of the Flashlight Housing can also be tailored to your specific requirements.

- Wall Thickness: We can control the wall thickness of the housing precisely, ensuring it is strong enough to protect the internal components while maintaining a lightweight design.

- Surface Finish: The critical surfaces of the Flashlight Housing have a surface finish of Ra 0.4μm, providing a smooth and attractive appearance.

We start by carefully selecting certified materials with uniform properties. For aluminum alloy Flashlight Housing, we source materials with the right combination of strength, lightweight, and heat – dissipation capabilities.

Our CNC grinding process creates the intricate shapes and profiles of the Flashlight Housing with a variation of ≤0.005mm. After machining, all components are ultrasonically cleaned to remove any debris or contaminants.

We perform dynamic balancing on the Flashlight Housing to G1.0 grade at operating conditions. Microscope inspection of the surfaces and edges is carried out to ensure there are no defects.

Our 2,000 sqm facility in Dongguan, China, is equipped with 5 – axis & 4 – axis CNC machining centers, Swiss – type CNC lathes, precision grinding & EDM machines, and stamping & die – casting units. Our team of 20+ years of experienced engineers oversees every step of the manufacturing process, ensuring that your Flashlight Housing is of the highest quality.

Partner With Us

“Your design vision, our engineering precision – let’s create something extraordinary.”

Request a Free Project Review

📧 Email: ganyuan1688@gmail.com

🌐 Website: ganyuan1688@gmail.com

📞 Tel: 86–13929256361

Dongguan Ganyuan Hardware Technology Co., Ltd.

Request a Free Quote Today!

📩 Send your drawings (PDF/STEP/IGS) for instant pricing

📞 Discuss your project with our engineering team