Product Categories

- Brass Parts (11)

- Plastic Parts (17)

- Aluminum alloy products/accessories (100)

- Precision Machinery Parts (195)

- Watch/Jewelry Accessories (6)

- Stainless Steel Products/Accessories (160)

- cnc turning parts (121)

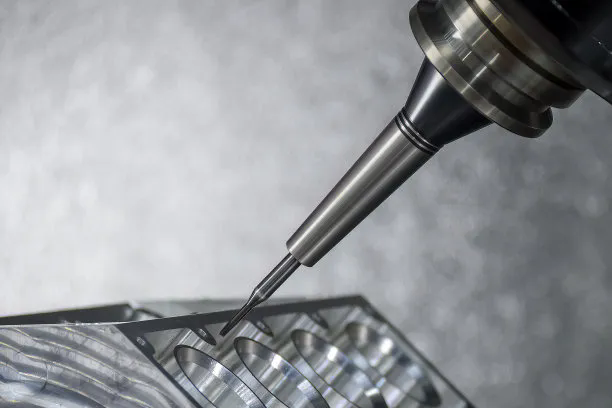

In today’s competitive industrial landscape, custom machined parts serve as the backbone of innovation across various sectors. Whether you’re in robotics, aerospace, electronics, or manufacturing, precision-engineered components tailored to your exact specifications can significantly enhance performance and efficiency.

| Production type | Custom production and processing | Material | Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting,cnc machined components |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | Dongguan, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts; Machining parts;custom machined parts |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

Our custom machined parts are meticulously crafted using advanced CNC machining techniques, ensuring superior accuracy, durability, and functionality. From motor shafts to titanium alloy interfaces, we provide solutions that meet the most demanding industrial requirements.Custom machined parts

High-performance custom machined parts with quick turnaround, supporting industries that demand reliability and precision engineering.

Every project has unique challenges, and off-the-shelf components often fall short. Our custom machined parts are designed using 5-axis CNC milling, CNC turning, and multi-axis machining, allowing us to produce intricate geometries with tight tolerances (±0.005mm).

We collaborate with high-quality material suppliers to offer a broad range of options:

Aluminum Alloys (6061, 6063, 7075) – Lightweight & corrosion-resistant

Stainless Steel (303, 304, 316) – High strength & durability

Titanium Alloys (TC4) – Ideal for aerospace & medical applications

Brass & Copper (H59, H62) – Excellent conductivity & machinability

Engineering Plastics (PEEK, POM, Nylon) – For specialized non-metallic needs

To enhance performance and aesthetics, we offer multiple surface treatments:

Anodizing (for aluminum corrosion resistance)

Electroplating (gold, nickel, zinc, chromium)

![]()

Hardening & Heat Treatment (for increased wear resistance)

Sandblasting & Polishing (for smooth finishes)

Robot accessory brackets (AL6061, CNC milled & oxidized)

Precision gears & couplings (stainless steel, hardened for longevity)

Titanium alloy interfaces (TC4, 5-axis CNC machined for high-strength connections)

Aviation plug components (lightweight, heat-resistant materials)

Microphone housings (AL6063, gold-oxidized for premium finish)

Fine-tuning dials (carbon steel, electroplated for precision adjustments)

Motor shaft sleeves (H59 brass, CNC turned & plated for reduced friction)

Motor shaft sleeves (H59 brass, CNC turned & plated for reduced friction)

Hydraulic system components (stainless steel, corrosion-resistant)

2,000+ sqm production plant in Dongguan, China

High-end CNC machines: 5-axis, 4-axis, multi-turning centers

Stamping & die-casting for high-volume production

Premium Packaging: Anti-static bags + Foam protection + Gift box options

OEM/ODM Services: Provide samples or drawings (PDF/STEP/IGS formats accepted)

Global Shipping: DHL/FedEx/Sea freight supported